contact us

Goldapple Aluminum Group

We provide customers with quality products and services.

If you would like to leave us a comment please go to

Contact Us

Aluminum possesses unique properties which makes it a great choice for the design engineer. Aluminum extrusions are available in an unlimited number of shapes, colors and physical properties to fit almost any requirement. When compared to stainless steel, aluminum’s flexibility easily make it the better option:

Lightweight

Many people know that aluminum is lightweight, but did you know it only weighs about 1/3 that of stainless steel? Aerospace and automotive engineers certainly do. Less weight equals lower operating costs for their customers.

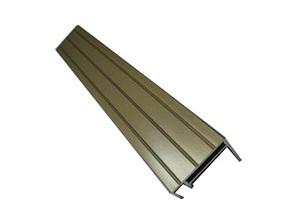

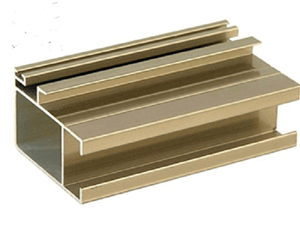

Geometries Are Almost Unlimited

Aluminum extrusions offer extraordinary design flexibility. Very complex profiles can be extruded. This allows the engineer to place material where he or she needs it for optimal strength while minimizing fabrication costs at the same time. There are many tube designs we produce, which simply could not be produced utilizing any other manufacturing process.

Unique Material Properties:

Once shapes are extruded, they can be formed in a variety of ways. Our bike wheel customers roll the extrusions into a hoop to form bike rims. Our satellite cooling customers make complex compound bends in forming their heat pipe cooling systems.

Colors & Coatings

Extruded aluminum can be anodized to enhance its appearance, improve wear resistance, and extend the life of the extrusion. The coating is naturally clear, and can be combined with organic dyes available in a rainbow of colors. Aluminum profiles can also be treated with chemical conversion coating to minimize oxidation. Chem film coating is specified in many aerospace applications. Anodize & chem film coating are also bio-compatible when used for disposable medical devices.

Low Tooling Cost

Extrusion dies are very inexpensive when compared to other types of tooling. The die cost for an extruded .350” diameter rod runs ~$500. For a .500” OD x .400” ID tube the die cost would run ~$1300. The most exotic dies are for multi-hollow, thin wall designs can cost over $3500. These exotic dies are the exception rather than the rule. Lead times vary from 2-4 weeks for the production of the tool.

Costs less than Stainless Steel

Aluminum extrusions are very cost effective. Compared to stainless steel tubes, extruded aluminum tubes can be up to 70% less expensive. In addition there are many examples of machined parts that have been redesigned using extrusions and the cost decreasing 30-40%.