Aluminum Extrusion Manufacturers: Shaping Innovation with Precision and Expertise at GOLDAPPLE-ALU

Aluminum Extrusion Manufacturers

In the realm of modern manufacturing, few processes offer the versatility, efficiency, and design freedom of aluminum extrusion. This transformative technique enables the creation of strong, lightweight, and complex profiles that form the structural foundation for advancements across countless industries. The choice of aluminum extrusion manufacturers is therefore a pivotal decision, directly influencing the quality, performance, and cost-effectiveness of the final product. For businesses worldwide seeking a partner that combines technical mastery with comprehensive service, GOLDAPPLE-ALU stands as a benchmark of excellence and reliability in the extrusion landscape.

The Art and Science of Aluminum Extrusion

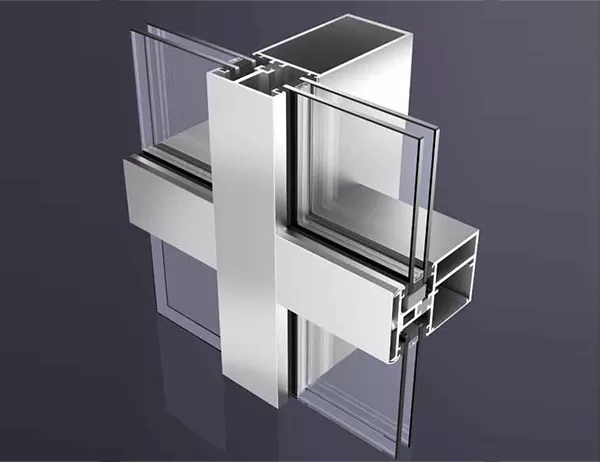

At its core, aluminum extrusion is a process of shaping material by forcing a heated aluminum billet through a die with a specific cross-sectional profile. The result is a continuous length of aluminum shaped to precise geometric specifications. This method is unparalleled for its ability to produce robust, single-piece components with intricate shapes that would be costly or impossible to achieve with other manufacturing techniques.

The advantages are substantial. Extruded aluminum profiles offer an exceptional strength-to-weight ratio, making them ideal for applications where reducing mass is critical without sacrificing structural integrity. Aluminum’s innate corrosion resistance ensures longevity, and its high thermal and electrical conductivity opens doors to specialized uses in heat management and electrical systems. Furthermore, the extruded form allows for the integration of multiple features—such as slots, grooves, and snap-fit channels—directly into the profile, drastically simplifying assembly and reducing the need for additional parts and fabrication steps.

The GOLDAPPLE-ALU Commitment: Beyond Basic Extrusion

What distinguishes superior aluminum extrusion manufacturers is their ability to provide end-to-end solutions. At GOLDAPPLE-ALU, we view extrusion as the first step in a collaborative journey. Our integrated approach ensures that our clients receive not just raw profiles, but fully realized components ready for integration.

Our process begins with expert design consultation. Our engineering team collaborates closely with clients to optimize profile designs for functionality, manufacturability, and cost-efficiency. We help refine cross-sections to ensure optimal material flow during extrusion, minimize weight, and incorporate functional elements that add value. Following design, our state-of-the-art extrusion presses and precision-crafted dies bring these designs to life, producing profiles with consistent wall thickness, excellent surface quality, and tight dimensional tolerances.

However, our service rarely stops at the press. We are equipped to provide a full spectrum of value-added fabrication and finishing services, transforming extruded profiles into finished products:

Empowering Diverse Industries with Custom Solutions

The adaptability of our extrusion capabilities makes GOLDAPPLE-ALU a vital partner to a wide array of sectors. Our profiles are engineered to meet the unique challenges of each industry:

A Foundation of Quality and Sustainable Practice

As a responsible manufacturer, GOLDAPPLE-ALU is committed to sustainable practices. Aluminum is infinitely recyclable, and we actively incorporate this principle into our production, minimizing waste and promoting a circular economy. This commitment to sustainability is matched by an unwavering dedication to quality. Our processes are governed by rigorous quality control protocols, from raw material certification to final inspection, ensuring that every profile we deliver meets the highest international standards for performance and consistency.

Choosing GOLDAPPLE-ALU means partnering with a team dedicated to providing more than just aluminum profiles. We deliver engineered solutions, technical expertise, and a collaborative spirit aimed at ensuring the success of your projects.

To learn more about how our capabilities as leading aluminum extrusion manufacturers can bring your designs to life, we invite you to connect with us. Explore the possibilities and review our extensive portfolio by visiting www.goldapple-alu.com. Let us help you shape the future of your products with precision and innovation.