Choosing the Right Industrial Aluminum Profile for Your Project: A Comprehensive Guide

In the world of industrial design, selecting the appropriate aluminum profile is paramount to the success of your project. Amidst a myriad of options, it’s crucial to navigate through the complexities of this vital material and make an informed decision.

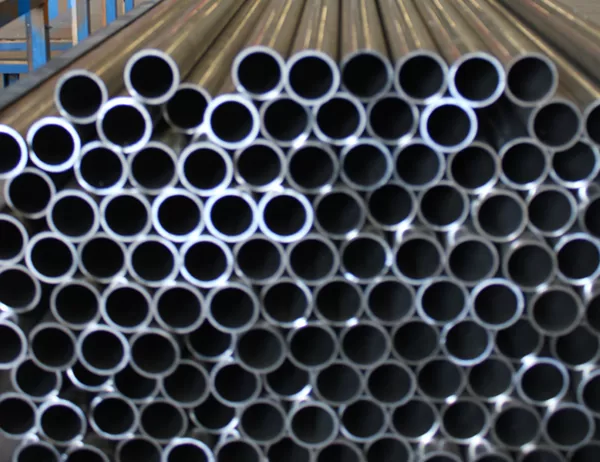

Properties and Applications of Industrial Aluminum Profiles

Industrial aluminum profiles are extruded shapes with specific cross-sectional geometries. They possess exceptional strength, durability, and corrosion resistance, making them ideal for various applications:

– Structural components: Frames, beams, columns

– Enclosures and housings: Machinery casings, panels

– Conveyor systems: Guide rails, frames

– Special applications: Jigs, fixtures, prototypes

Factors to Consider

Selecting the right profile involves carefully considering several factors:

1. Strength and Load Requirements: Determine the expected loads and stresses the profile will encounter. Choose a profile with sufficient cross-sectional area to withstand these forces.

2. Corrosion Resistance: Aluminum’s inherent corrosion resistance is enhanced by various surface treatments. Consider the operating environment and choose profiles with appropriate treatments.

3. Formability: If complex shapes or bends are required, select profiles that can be easily formed without compromising strength.

4. Dimensional Tolerances: Ensure the dimensions of the profile meet your manufacturing and assembly requirements.

5. Cost: Consider the budget and compare prices from different suppliers. However, prioritize quality over cost to avoid future issues.

Selecting a Supplier

Partnering with a reliable supplier is essential. Look for companies with:

– Extensive experience: Choose suppliers with a proven track record in manufacturing industrial aluminum profiles.

– Technical expertise: Seek guidance from knowledgeable professionals who can assist you in profile selection and design optimization.

– Quality certifications: Ensure the supplier meets industry standards and has certifications such as ISO 9001 or AS9100.

Conclusion

Choosing the right industrial aluminum profile is a critical step in ensuring the success of your project. By understanding the properties, applications, and factors to consider, you can make an informed decision. Partnering with a reliable supplier can provide invaluable support and ensure the delivery of high-quality profiles that meet your specific requirements. By following these guidelines, you can unlock the full potential of industrial aluminum profiles and pave the way for innovative and successful projects.