Aluminum frame profiles offer a wide range of customization options that allow architects, designers, and engineers to create structures that meet specific aesthetic, functional, and performance requirements. These options include:

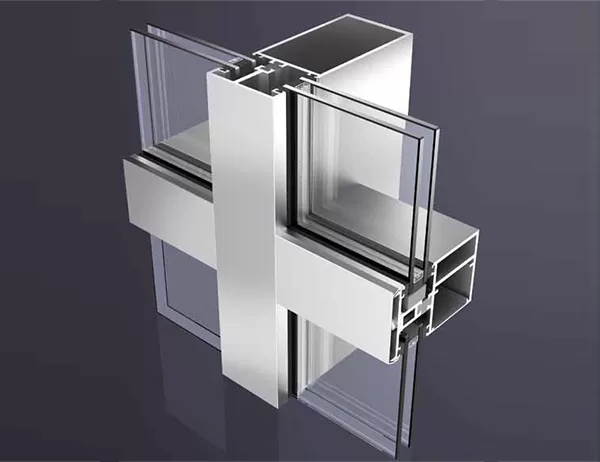

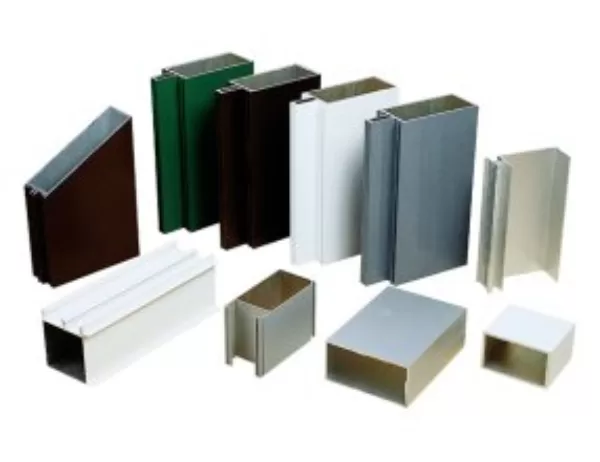

Aluminum profiles can be extruded into various shapes, from simple rectangular tubes to complex custom designs. This flexibility enables the creation of frames that can accommodate different architectural styles and functional needs. Additionally, profiles can be cut to specific lengths and joined together using connectors or welding, providing further flexibility in size and shape.

Aluminum frame profiles can be finished with various coatings to achieve desired aesthetic effects and enhance durability. Common finishes include:

– Anodizing: An electrochemical process that creates a protective oxide layer, providing corrosion resistance and a range of colors.

– Powder Coating: A dry powder paint that is electrostatically applied and cured at high temperatures, resulting in a durable and scratch-resistant finish.

– Clear Anodizing: A transparent finish that protects the aluminum while maintaining its metallic appearance.

Aluminum frame profiles can be designed with thermal breaks to improve thermal insulation. Thermal breaks are inserts made of materials with low thermal conductivity, such as polyamide or polyurethane, that prevent heat transfer through the frame. This feature is crucial in reducing energy consumption and improving occupant comfort.

The strength and durability of aluminum frame profiles are determined by their alloy composition and heat treatment. Different alloys and heat treatments provide varying levels of tensile strength, yield strength, and hardness. By carefully selecting the appropriate alloy and heat treatment, frames can be designed to withstand specific loads and environmental conditions.

Aluminum is naturally resistant to corrosion, but it can be further enhanced through various treatments. Anodizing, powder coating, and chromate conversion coatings provide additional protection against corrosion, ensuring the longevity of the structure.

Aluminum is a sustainable material that can be recycled indefinitely. It is estimated that around 75% of all aluminum ever produced is still in use today. Recycling and using recycled aluminum significantly reduce the environmental impact of frame production.

Customization options available with aluminum frame profiles offer architects, designers, and engineers an unprecedented level of flexibility and control in creating structures that fulfill aesthetic, functional, and performance requirements. From shape and size to surface finishes, thermal performance, and structural integrity, the versatility of aluminum makes it an ideal choice for a wide range of applications in construction and architecture.