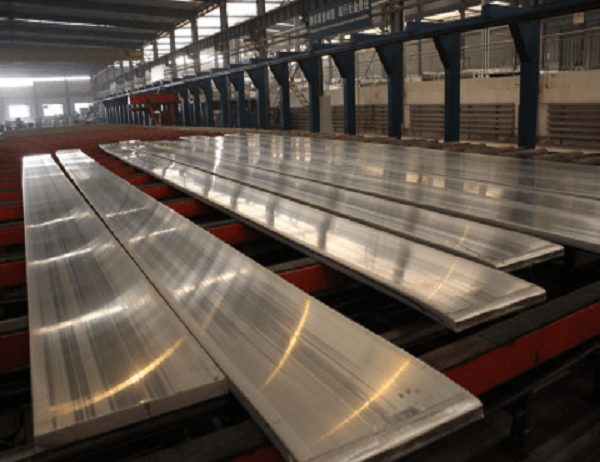

Aluminium is a versatile and widely used metal in the construction industry, particularly in the form of track profiles. However, traditional manufacturing processes can have adverse environmental impacts. Eco-friendly practices in aluminium track profile manufacturing aim to minimize these impacts and promote sustainability throughout the production chain.

Material Optimization and Recycling

Reducing the consumption of virgin aluminium through material optimization and recycling are crucial aspects of eco-friendly manufacturing. By using recycled aluminium, manufacturers can conserve natural resources, reduce energy consumption, and prevent waste accumulation. Advanced techniques such as closed-loop recycling systems enable the efficient recovery of scrap generated during the production process.

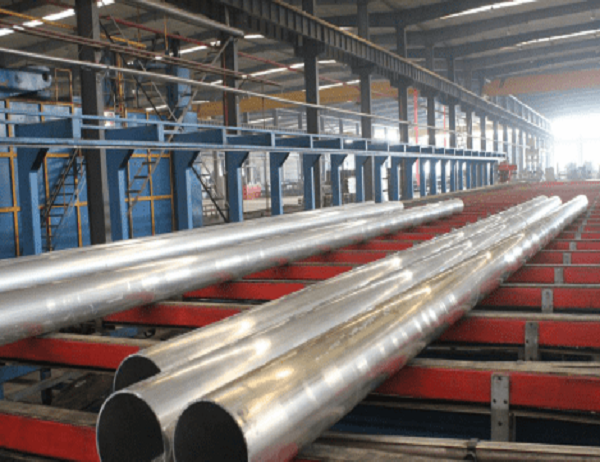

Energy Efficiency

Aluminium track profile manufacturing requires significant energy consumption. Implementing energy-efficient practices can substantially reduce carbon emissions and operating costs. Investing in energy-efficient equipment, optimizing production processes, and utilizing renewable energy sources, such as solar or wind power, contribute to a more sustainable production approach.

Water Conservation

Water is an essential resource in the manufacturing process, particularly for cooling and cleaning. Eco-friendly practices prioritize water conservation. Employing closed-loop water systems, installing water-saving fixtures, and implementing rainwater harvesting techniques can significantly reduce water usage.

Waste Reduction and Byproduct Utilization

Minimizing waste and finding beneficial uses for byproducts are essential for sustainable manufacturing. Implementing waste management strategies, such as segregation and recycling programs, ensures that waste materials are diverted from landfills. Additionally, recovering and utilizing byproducts, such as aluminium dross or fly ash, as raw materials in other industries promotes circularity and reduces environmental impact.

Sustainable Transport and Packaging

Transportation and packaging of aluminium track profiles can also contribute to environmental sustainability. Utilizing energy-efficient vehicles, optimizing logistics, and employing eco-friendly packaging materials, such as recycled cardboard or biodegradable options, reduce carbon emissions and promote sustainable practices throughout the supply chain.

Compliance and Certifications

Adhering to environmental regulations and obtaining industry certifications demonstrate a commitment to eco-friendly manufacturing. Certifications such as ISO 14001 or LEED (Leadership in Energy and Environmental Design) provide independent verification of environmental performance and sustainability practices.

Continuous Improvement and Innovation

Eco-friendly manufacturing is an ongoing journey that requires continuous improvement and innovation. Manufacturers should regularly assess their environmental performance, identify areas for improvement, and invest in research and development of new technologies that promote sustainability. By embracing a culture of innovation and collaboration, the industry can drive progress towards a greener future for aluminium track profile manufacturing.

Conclusion

Eco-friendly practices in aluminium track profile manufacturing are essential for ensuring the sustainability of the industry and preserving our environment for future generations. By optimizing materials, reducing energy consumption, conserving water, minimizing waste, embracing sustainable transport and packaging, adhering to regulations, and continuously innovating, manufacturers can significantly reduce their environmental footprint and contribute to a more sustainable built environment.