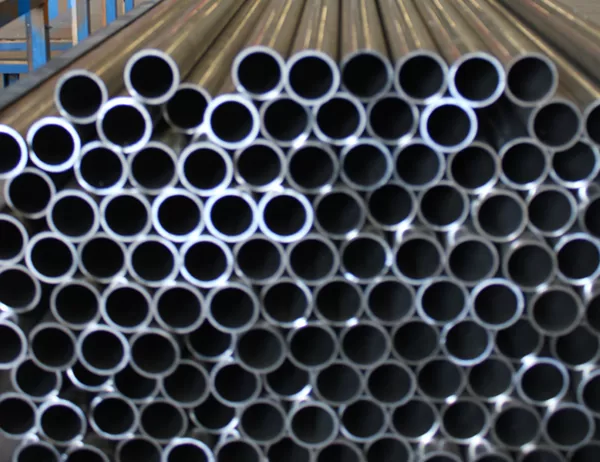

Embark on a captivating journey into the realm of aluminium alloy tubing, where strength and versatility intertwine. This guide delves into the nuances of aluminium alloys, their characteristics, and how they empower engineers to craft innovative solutions.

Introduction:

Aluminium alloy tubing, a marvel of metallurgical engineering, has become indispensable in industries ranging from aerospace to construction. Its unique blend of lightweight, high strength, and corrosion resistance makes it an ideal choice for applications demanding both performance and longevity.

Understanding Aluminium Alloys:

Aluminium alloys are formed by combining aluminium with other elements, such as copper, magnesium, manganese, and silicon. These elements alter the properties of pure aluminium, enhancing its strength, hardness, and other characteristics. Common aluminium alloy series include the 2000, 3000, 5000, and 6000 series, each tailored to specific applications.

Characteristics of Aluminium Alloy Tubing:

– High Strength-to-Weight Ratio: Aluminium alloy tubing offers exceptional strength without adding excessive weight. This makes it ideal for lightweight structures where strength and efficiency are paramount.

– Corrosion Resistance: Aluminium naturally forms a protective oxide layer, enhancing its resistance to corrosion. This feature extends the lifespan of structures exposed to harsh environments.

– Weldability: Aluminium alloy tubing can be easily welded, providing versatility for complex designs and repairs.

– Extrusion and Bending: The malleability of aluminium alloys allows for precise extrusion and bending processes, creating intricate shapes and profiles.

Applications of Aluminium Alloy Tubing:

The applications of aluminium alloy tubing are boundless. It’s extensively used in:

– Aerospace structures

– Automotive frames

– Marine vessels

– Architectural cladding

– Energy and heat exchange systems

– Medical devices

Choosing the Right Alloy:

Selecting the appropriate aluminium alloy for a specific application is crucial. Factors to consider include:

– Strength Requirements: Alloys with higher alloying elements, such as 7075 and 6082, provide superior strength.

– Corrosion Resistance: Alloys with high magnesium content, like 5083 and 5052, excel in harsh environments.

– Weldability: Alloys with specific alloying combinations, like 5356 and 6061, offer excellent weldability.

Conclusion:

Aluminium alloy tubing is a versatile and valuable material that empowers engineers to design innovative and durable structures. Understanding its characteristics and properties enables informed decision-making and ensures optimal performance in a wide range of applications. As the demand for lightweight, high-strength materials continues to grow, aluminium alloy tubing will undoubtedly remain an essential part of the engineering landscape.