In the realm of industrial construction, the choice between extruded aluminum pipes and steel pipes often hinges on their strength and durability. While both materials have their merits, understanding their distinct characteristics is crucial for informed decision-making.

Strength: The Aluminum Edge

Pound for pound, extruded aluminum pipes possess exceptional strength, often surpassing steel in this regard. The extrusion process, which forces aluminum through a precise die, enhances grain alignment and improves material integrity. This translates to a higher tensile strength, enabling aluminum pipes to withstand significant loads without bending or breaking.

Durability: Steel’s Resilience

Steel pipes, on the other hand, boast superior durability and resistance to corrosion and oxidation. Their ferrous nature forms a protective oxide layer on their surface, effectively shielding them from the elements. In harsh environments, such as coastal areas or chemical plants, steel pipes exhibit remarkable longevity over aluminum.

Weight: Aluminum’s Featherweight Advantage

Weight is often a determining factor in selecting pipes. Extruded aluminum pipes are significantly lighter than their steel counterparts, making them easier to handle, install, and transport. This weight advantage can result in reduced labor costs and improved efficiency during construction projects.

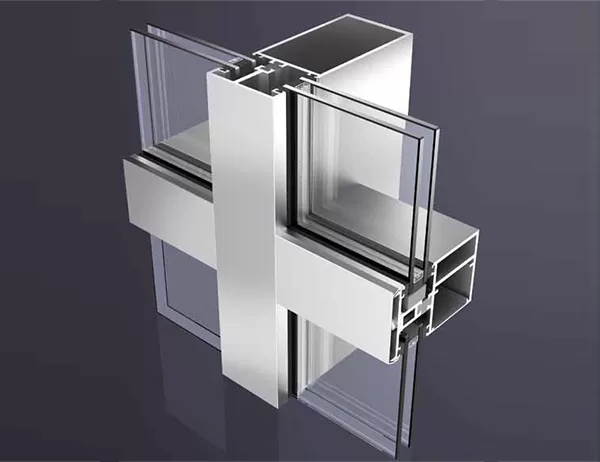

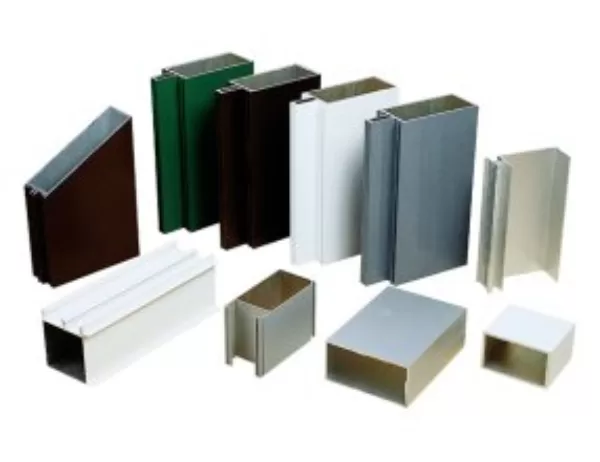

Versatility: Aluminum’s Adaptability

Aluminum pipes offer exceptional versatility, lending themselves to a wide range of applications. Their non-magnetic properties make them suitable for use in sensitive environments, such as medical facilities and electronic manufacturing. Additionally, aluminum can be easily anodized to enhance its surface durability and aesthetic appeal.

Cost: A Matter of Perspective

The cost of aluminum pipes and steel pipes varies depending on factors such as size, thickness, and quantity. While aluminum pipes may have a higher upfront cost, their lower maintenance requirements and longer lifespan can offset these expenses over time.

Conclusion

The choice between extruded aluminum pipes and steel pipes is a delicate balance between strength, durability, weight, versatility, and cost. Aluminum pipes offer exceptional strength and weight advantages but may face limitations in durability. Steel pipes, with their superior durability and corrosion resistance, excel in harsh environments but may be more cumbersome to handle. By carefully considering the specific requirements of each application, engineers can make informed decisions that maximize performance and longevity.