In the realm of engineering materials, aluminum alloys reign supreme due to their exceptional combination of lightweight, strength, and corrosion resistance. Among these alloys, 6101 aluminum alloy stands out as a remarkable choice for applications demanding both high electrical conductivity and mechanical integrity. This article will explore how 6101 aluminum alloy achieves these remarkable attributes.

6101 aluminum alloy exhibits superior electrical conductivity, making it highly suitable for electrical applications. This conductivity stems from the alloy’s composition, which primarily consists of aluminum with trace amounts of magnesium and silicon. These alloying elements disrupt the crystal lattice of aluminum, reducing electrical resistance and allowing charges to flow more freely.

Moreover, the 6101 alloy undergoes a T8 tempering process, which involves solution heat treatment followed by rapid quenching. This process strengthens the alloy while maintaining its electrical properties. By refining the grain structure and reducing defects, the T8 tempering enhances conductivity, making 6101 aluminum ideal for electrical conductors, busbars, and other components requiring efficient current transfer.

Apart from its electrical prowess, 6101 aluminum alloy also possesses exceptional mechanical strength. The alloy’s high magnesium content contributes to solid solution strengthening, where magnesium atoms dissolve into the aluminum lattice, hindering dislocation movement and increasing resistance to deformation.

The T8 temper further enhances the alloy’s strength by introducing precipitation strengthening. During aging at elevated temperatures, fine precipitates of magnesium silicide form within the aluminum matrix. These precipitates act as barriers to dislocation movement, further strengthening the alloy without compromising its electrical conductivity.

While 6101 aluminum alloy excels in both conductivity and strength, it’s worth noting the potential trade-off between these properties. Generally, increasing the strength of an alloy tends to decrease its conductivity. However, in the case of 6101 aluminum, the T8 tempering process allows for a balance between these attributes.

The rapid quenching involved in T8 tempering prevents excessive precipitation formation, preserving the alloy’s electrical conductivity while enhancing its strength. This careful balance makes 6101 aluminum a viable choice for applications where both high conductivity and mechanical resilience are crucial.

The unique combination of conductivity and strength of 6101 aluminum alloy makes it suitable for a wide range of applications. It is commonly used in:

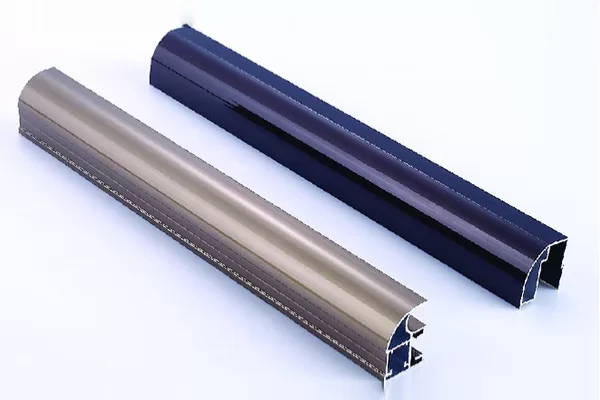

Electrical conductors and busbars

Automotive components, such as engine blocks and pistons

Aerospace components, including fuselage panels and wing spars

Marine structures, such as boat hulls and offshore platforms

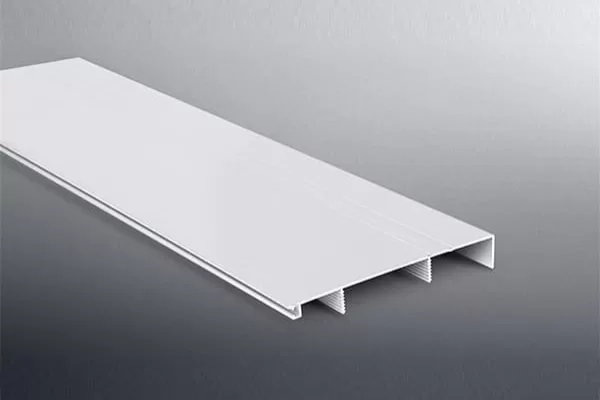

Construction, as roofing and cladding materials

6101 aluminum alloy is a remarkable material that offers exceptional electrical conductivity and mechanical strength. Through careful alloying and advanced tempering processes, this alloy achieves a unique balance of properties that makes it ideal for applications demanding both high current flow and structural integrity. As a result, 6101 aluminum alloy finds its place in a variety of industries, from electrical to automotive, aerospace, and beyond.