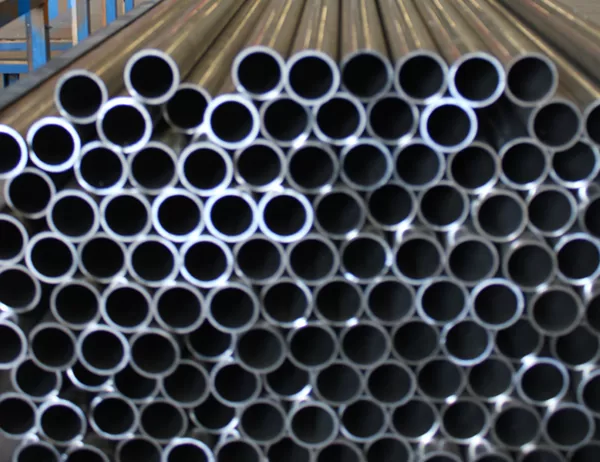

Extruded aluminum pipes have emerged as a revolutionary material in various industries, offering a unique combination of performance and durability. Their exceptional properties make them an ideal choice for applications demanding strength, corrosion resistance, and lightweight construction. This article delves into the multifaceted ways extruded aluminum pipes enhance performance and durability, providing insights into their remarkable benefits.

Enhanced Mechanical Strength

Extruded aluminum pipes possess exceptional mechanical strength, making them capable of withstanding high loads and pressures. The extrusion process aligns the grain structure of the aluminum, resulting in a more uniform and robust material. This enhanced strength enables these pipes to endure heavy-duty applications without compromising their structural integrity.

Corrosion Resistance

Another key advantage of extruded aluminum pipes is their remarkable corrosion resistance. Aluminum’s natural oxide layer forms a protective barrier that effectively protects the metal from the corrosive effects of various environmental factors, such as moisture, chemicals, and salt. This corrosion resistance ensures the longevity of the pipes, minimizing the need for maintenance and replacement.

Lightweight Construction

Extruded aluminum pipes are exceptionally lightweight, offering significant advantages in transportation and installation. Their low weight facilitates easy handling and reduces the overall weight of the structure, leading to increased efficiency and reduced energy consumption. The lightweight nature of these pipes also makes them suitable for applications where weight is a critical factor, such as in aerospace and automotive industries.

Superior Formability

Extruded aluminum pipes are highly formable, allowing them to be bent, shaped, and formed into complex geometries without compromising their strength. This formability enables the fabrication of customized shapes and intricate designs, meeting the diverse requirements of various applications. The ability to shape the pipes into complex geometries also enhances their structural stability and rigidity.

Excellent Thermal Conductivity

Extruded aluminum pipes exhibit excellent thermal conductivity, facilitating efficient heat transfer. This property makes them ideal for applications involving heat dissipation or thermal management, such as in heat exchangers and radiators. The efficient heat transfer capabilities of these pipes contribute to optimal performance and reliability in thermal systems.

Versatility and Applications

Extruded aluminum pipes find applications across a wide range of industries due to their versatile properties. Their strength, corrosion resistance, and lightweight construction make them suitable for structural, piping, and transportation applications. They are commonly used in construction, automotive, aerospace, shipbuilding, and chemical processing industries, among others.

Conclusion

Extruded aluminum pipes are an exceptional choice for applications demanding performance and durability. Their enhanced mechanical strength, corrosion resistance, lightweight construction, superior formability, excellent thermal conductivity, and versatility make them a valuable material for various industries. The remarkable properties of extruded aluminum pipes ensure long-lasting performance, reduced maintenance costs, and increased efficiency in a wide range of applications.