Industrial Aluminum Profile: The Backbone of Modern Manufacturing and Automation

Industrial Aluminum Profile

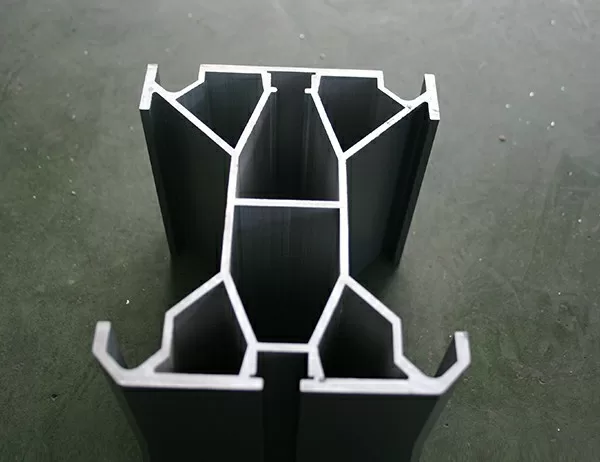

In the dynamic world of industrial manufacturing, efficiency, durability, and adaptability are not just desirable traits—they are essential for success. At the heart of countless automated systems, machinery frameworks, and production lines lies a critical component that makes this possible: the industrial aluminum profile. These extruded structural elements form the versatile, robust, and reusable skeletons upon which modern industry is built. For engineers and project managers seeking a reliable source for these foundational components, GOLDAPPLE-ALU has established itself as a premier partner, delivering precision-engineered profiles that empower innovation and drive operational excellence.

Why Industrial Aluminum Profiles are the Engineer’s Choice

The dominance of aluminum profiles in industrial applications is a direct result of their unparalleled combination of physical and practical benefits. Unlike traditional materials like steel or wood, industrial aluminum profiles offer a unique set of advantages that are perfectly suited to the demands of a fast-paced, precision-driven environment.

GOLDAPPLE-ALU: Engineering Solutions, Not Just Supplying Products

At GOLDAPPLE-ALU, we understand that an industrial aluminum profile is more than a piece of metal; it is a fundamental building block for our clients’ success. Our approach is rooted in a deep commitment to engineering partnership and comprehensive service. We work collaboratively with our clients from the initial concept stage, providing expert design consultation to ensure the selected profile meets the specific mechanical, spatial, and budgetary requirements of the project.

Our manufacturing prowess is built on a foundation of advanced technology and stringent quality control. We utilize state-of-the-art extrusion presses and precision-crafted dies to produce profiles with consistent geometry, excellent surface finish, and tight dimensional tolerances. This commitment to precision ensures that every GOLDAPPLE-ALU profile fits perfectly and performs reliably in the most demanding applications.

Beyond extrusion, we provide a full suite of value-added services to deliver ready-to-install components:

Powering Diverse Industrial Applications

The versatility of our industrial aluminum profiles makes them indispensable across a broad spectrum of sectors. GOLDAPPLE-ALU components are hard at work in:

A Partnership for a Smarter, More Efficient Future

Choosing GOLDAPPLE-ALU means more than selecting a supplier; it means forging a partnership with a team dedicated to quality, innovation, and your success. We are committed to sustainable manufacturing practices, recognizing that the recyclability of aluminum aligns with the goals of forward-thinking industries. Our rigorous quality assurance protocols guarantee that every profile we deliver contributes to the reliability and longevity of your equipment.

We invite you to experience the GOLDAPPLE-ALU difference. Discover how our expertise in industrial aluminum profiles can provide the strong, adaptable, and cost-effective foundation your next project requires.

Explore our extensive capabilities and product portfolio by visiting www.goldapple-alu.com. Let us help you build the future of industry, one profile at a time.