In the realm of renewable energy, solar panels have emerged as a transformative technology, harnessing the sun’s energy to generate electricity. Aluminum extrusion plays a crucial role in the construction of these panels, providing lightweight, durable, and efficient frames. Recent advancements in aluminum extrusion technology have further enhanced the performance and reliability of solar panels, driving their widespread adoption.

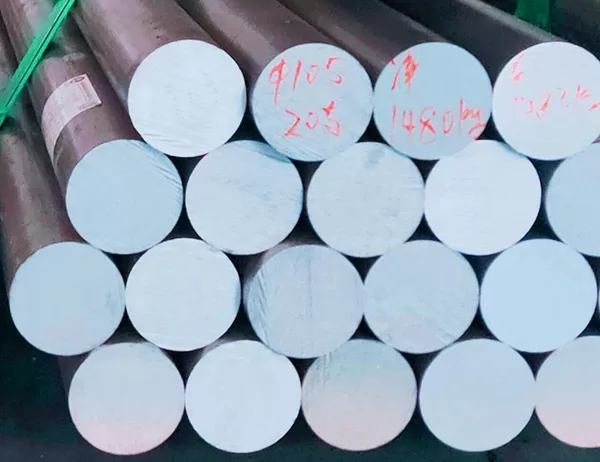

Innovative extrusion techniques have resulted in aluminum frames with increased strength and durability. By optimizing alloy compositions and extrusion parameters, manufacturers can create frames that can withstand extreme weather conditions, including high winds, heavy snow loads, and temperature fluctuations. These frames provide robust support for the delicate photovoltaic cells, ensuring their protection and longevity.

Solar panels generate heat during operation, which can reduce their efficiency. Advanced extrusion technology incorporates thermal management features into the frames. Through precise design and heat sink integration, frames effectively dissipate heat away from the cells, reducing temperature-related losses and maximizing power output.

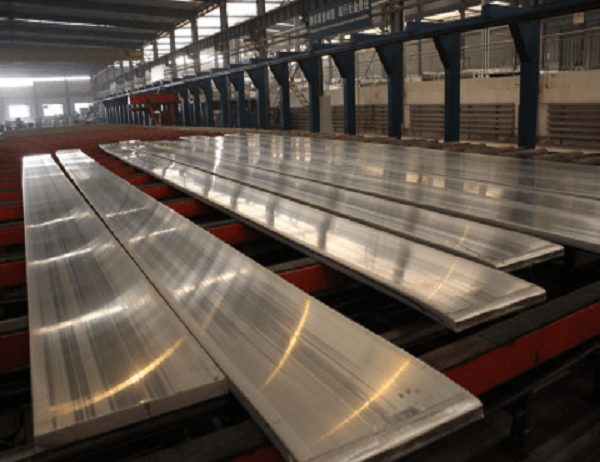

Extrusion processes have been refined to produce lightweight aluminum frames without compromising strength. This reduced weight facilitates easy installation and transportation, lowering project costs. Additionally, advancements in extrusion efficiency and material optimization have contributed to cost reductions, making solar panels more accessible and affordable.

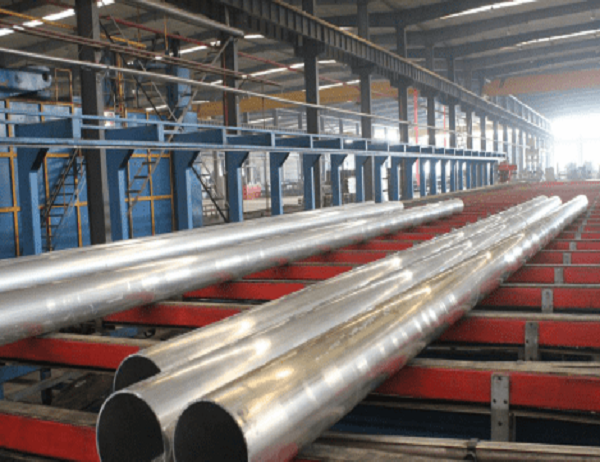

Modern extrusion technology allows for the creation of customized frame designs. Manufacturers can tailor frames to specific panel sizes, roof configurations, and aesthetic requirements. This flexibility enables optimal integration of solar panels into various architectural styles and building designs.

For efficient electrical transmission, aluminum frames are designed with enhanced electrical conductivity. Through alloy selection and surface treatments, frames minimize electrical resistance, ensuring seamless current flow between the photovoltaic cells and the electrical grid.

Aluminum extrusion fosters sustainability in solar energy. Aluminum is a highly recyclable material, allowing for the recovery and reuse of frames at the end of their lifespan. Additionally, the energy-efficient extrusion processes minimize environmental impact, contributing to the overall sustainability of solar panel systems.

Advancements in aluminum extrusion technology have revolutionized the manufacturing of solar panels, enabling increased strength, improved thermal management, reduced weight and cost, customizable designs, enhanced electrical conductivity, and environmental sustainability. These innovations play a vital role in the growing adoption of solar energy, contributing to a cleaner and more sustainable future.