In the realm of engineering, extruded aluminum tubes have emerged as transformative elements, shaping industries and unlocking unimaginable possibilities. Their unique properties and versatility have propelled them to the forefront of innovation, where they seamlessly merge functionality and aesthetics.

Lightweight Strength

Extruded aluminum tubes possess exceptional strength-to-weight ratios, enabling them to withstand significant forces while remaining lightweight. This remarkable attribute has made them an indispensable material for applications such as aerospace, where weight optimization is crucial. From aircraft fuselages to landing gear, extruded aluminum tubes provide the necessary durability and reliability in demanding environments.

Corrosion Resistance

Aluminum’s natural resistance to corrosion makes extruded tubes ideal for applications exposed to harsh elements. They are unaffected by saltwater, humidity, and chemicals, ensuring longevity and maintaining their structural integrity over extended periods. This attribute has made extruded aluminum tubes indispensable in marine, chemical, and food processing industries.

Formability and Versatility

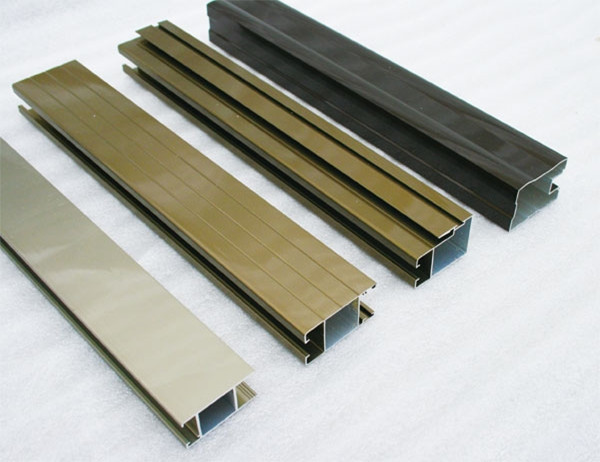

The extrusion process allows for the precise shaping of aluminum tubes, creating intricate geometries that would be impossible with other manufacturing methods. This formability has opened up countless opportunities in product design, resulting in tubes with complex cross-sections, internal fins, and custom profiles.

Heat Dissipation

Extruded aluminum tubes exhibit excellent thermal conductivity, making them efficient heat sinks. This property has revolutionized the design of electronic devices, where overheating can be a critical issue. By utilizing extruded aluminum tubes, designers can effectively manage heat dissipation, ensuring the optimal performance and longevity of sensitive electronic components.

Sustainability

Aluminum is one of the most recyclable materials, making extruded aluminum tubes an environmentally friendly choice. Their recyclability reduces waste and promotes sustainability, contributing to a circular economy. By incorporating extruded aluminum tubes into products, manufacturers demonstrate their commitment to responsible manufacturing practices.

Conclusion

Extruded aluminum tubes are the epitome of innovation, combining strength, lightness, corrosion resistance, formability, and thermal conductivity. Their versatility has made them indispensable in a wide array of industries, from aerospace and marine to electronics and construction. As engineers continue to explore the boundaries of extruded aluminum tubes, we can expect even more groundbreaking applications that will shape the future of technology and design.