Extruded aluminium tubes are widely used in various industries due to their exceptional properties and versatility. This article provides a comprehensive introduction to extruded aluminium tubes, covering their manufacturing process, key characteristics, applications, and benefits.

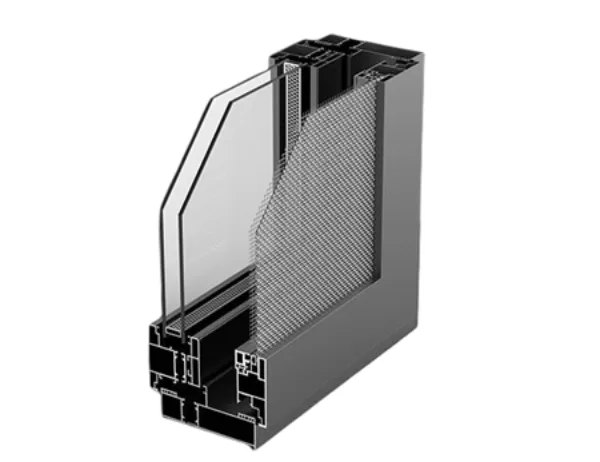

Extruded aluminium tubes are manufactured through a process known as extrusion. In this process, a heated aluminium billet is forced through a die, resulting in a continuous tube with the desired cross-sectional shape. The extrusion process can be customized to achieve a wide range of tube sizes, shapes, and finishes.

Extruded aluminium tubes possess several key characteristics that make them suitable for various applications:

Lightweight: Aluminium is a lightweight material, making extruded aluminium tubes easier to handle and transport.

Corrosion Resistant: Aluminium naturally forms a protective oxide layer that protects it from corrosion, ensuring longevity and durability.

Strength and Durability: Extruded aluminium tubes exhibit excellent strength-to-weight ratios, providing both structural integrity and resistance to mechanical stress.

Versatility: Extruded aluminium tubes can be formed into various shapes and sizes, allowing for customization to meet specific design requirements.

Extruded aluminium tubes find extensive use in a wide range of industries, including:

Aerospace: Lightweight and strong aluminium tubes are used in aircraft structures, landing gear, and hydraulic systems.

Automotive: Extruded aluminium tubes are employed in chassis components, bumpers, and structural reinforcements.

Construction: Aluminium tubes are utilized in window frames, curtain walls, and building facades.

Consumer Goods: Extruded aluminium tubes are found in products such as sporting goods, furniture, and appliances.

The use of extruded aluminium tubes offers numerous advantages:

Cost-Effective: Aluminium is a relatively affordable material, making extruded aluminium tubes a cost-effective choice for many applications.

Lightweight and Portable: The lightweight nature of aluminium tubes facilitates easy handling and transportation, reducing overall project costs.

Environmental Sustainability: Aluminium is highly recyclable, making extruded aluminium tubes an environmentally sustainable option.

Aesthetic Appeal: Extruded aluminium tubes can be anodized or coated in a variety of finishes, providing a sleek and modern aesthetic.

Extruded aluminium tubes are versatile and reliable components that offer numerous benefits for a diverse range of applications. Their lightweight, corrosion resistance, strength, and versatility make them an optimal choice for industries seeking durability, cost-effectiveness, and environmental sustainability. Understanding the manufacturing process, key characteristics, applications, and benefits of extruded aluminium tubes is crucial for selecting the appropriate tubes for specific project requirements.