In the realm of engineering and construction, where precision and durability reign supreme, the selection of aluminum extrusion suppliers holds paramount importance. Extruding aluminum, a process that transforms molten aluminum into complex shapes, demands meticulous attention to detail and unwavering quality standards. To ensure optimal outcomes, it is imperative to scrutinize key factors that distinguish exceptional suppliers from the ordinary.

1. Manufacturing Capabilities:

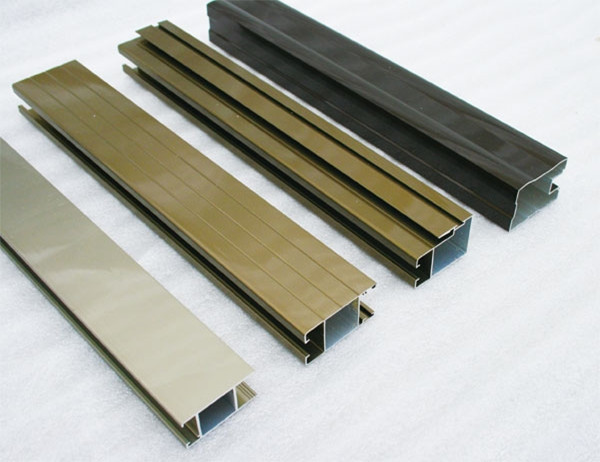

A supplier’s ability to meet your specific extrusion requirements is non-negotiable. Assess their machinery, technology, and expertise. Verify that they possess the capabilities to produce the desired shapes, sizes, tolerances, and finishes. Inquire about their in-house capabilities for anodizing, powder coating, and other surface treatments.

2. Quality Control:

Quality should permeate every aspect of the supplier’s operations. Seek suppliers with a proven track record of delivering high-quality extrusions that meet industry standards. ISO certifications, such as ISO 9001, provide evidence of a robust quality management system. Investigate their quality control processes to ensure they align with your own expectations.

3. Design and Engineering Expertise:

Collaboration with a supplier that offers design and engineering expertise can streamline your project. Look for suppliers who can assist in optimizing designs, reducing material waste, and enhancing functionality. Their knowledge and experience can save you time and money in the long run.

4. Lead Times and Delivery:

Timely delivery is crucial for efficient project execution. Determine the supplier’s lead times and adherence to delivery schedules. Consider their capacity and ability to meet your production demands. Explore their logistics capabilities and network to ensure seamless transportation and on-time delivery.

5. Customer Service and Support:

Excellent customer service fosters a mutually beneficial relationship. Choose suppliers who are responsive, communicative, and proactive in addressing your needs. Look for a supplier who is willing to go the extra mile to provide technical support, design assistance, and customized solutions.

6. Sustainability and Compliance:

Environmental consciousness and regulatory compliance are increasingly important considerations. Ensure that the supplier adheres to environmentally responsible practices and meets industry standards for safety, health, and the environment. Verify their certifications and commitment to sustainability.

By carefully evaluating these key factors, you can make an informed decision that will yield high-quality aluminum extrusions, timely deliveries, exceptional customer service, and sustainable practices. Remember, the right supplier can elevate your projects and contribute to their long-term success.