Aluminum track profiles have gained widespread recognition in various industries due to their exceptional properties and versatility. Whether it’s for constructing sliding doors and windows, building frameworks, or creating machinery components, these profiles offer a multitude of advantages that set them apart from traditional materials. In this article, we will delve into the key features and benefits of aluminum track profiles, highlighting why they have become the preferred choice for a myriad of applications.

One of the most notable advantages of aluminum track profiles is their exceptional corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface, which shields it from rust and degradation caused by exposure to moisture, chemicals, and harsh environments. This inherent characteristic makes aluminum track profiles ideal for outdoor applications, where they can withstand the elements without compromising their integrity or aesthetics.

Aluminum is renowned for its high strength-to-weight ratio, making it an incredibly robust material for track profiles. Despite their lightweight nature, aluminum track profiles exhibit excellent load-bearing capabilities and can withstand significant forces without bending or warping. Additionally, aluminum is highly durable and can endure extended periods of wear and tear without losing its shape or performance.

Aluminum track profiles are manufactured using precision extrusion processes, ensuring exceptional dimensional accuracy and consistency. This high level of precision allows for seamless integration with other components and guarantees a secure and proper fit. The tight tolerances of aluminum track profiles minimize friction and ensure smooth operation, making them ideal for applications requiring precision movement.

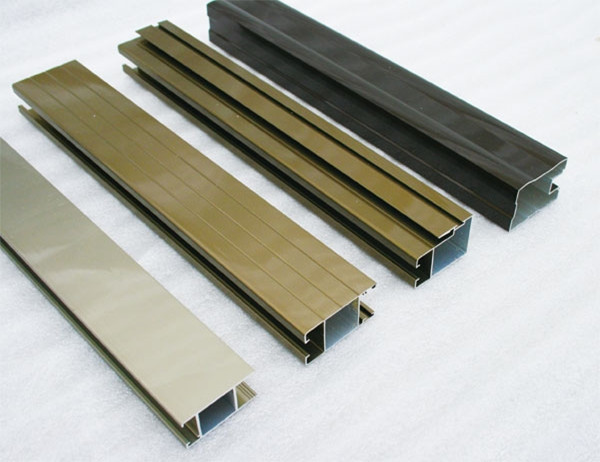

Aluminum track profiles offer unmatched versatility, as they can be easily customized to meet specific application requirements. They can be cut, bent, and perforated to accommodate various shapes and configurations. Additionally, aluminum track profiles are available in a wide range of sizes, thicknesses, and finishes, providing engineers and designers with the flexibility to create unique and functional solutions.

Aluminum track profiles are designed to be easy to install and maintain. Their lightweight nature makes handling and assembly effortless, reducing labor costs and installation time. The corrosion-resistant properties of aluminum also minimize the need for frequent maintenance and ensure long-term reliability. Simple cleaning and lubrication suffice to maintain the optimal performance of aluminum track profiles.

Aluminum is a highly sustainable material that can be recycled indefinitely without losing its inherent properties. This eco-friendly aspect makes aluminum track profiles a responsible choice for those concerned about the environmental impact of their construction or manufacturing projects. Additionally, aluminum is non-toxic and does not emit harmful fumes or pollutants.

The key features and advantages of aluminum track profiles make them an exceptional choice for a wide range of applications. Their corrosion resistance, strength, durability, precision, versatility, ease of installation, and sustainability set them apart from traditional materials and contribute to their growing popularity. Whether you’re designing sliding systems, building frameworks, or creating industrial machinery, aluminum track profiles offer a combination of functionality, reliability, and aesthetic appeal that is unmatched by other materials.