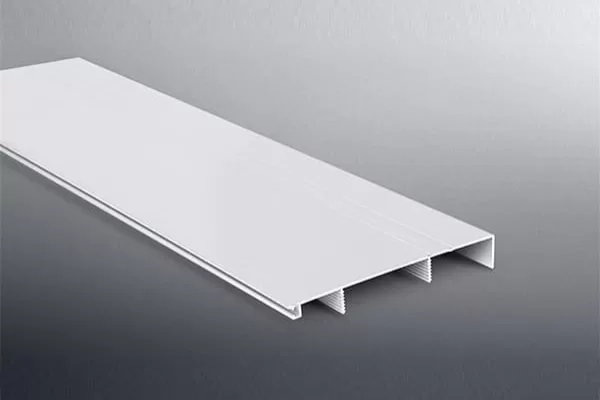

In the realm of thermal management, aluminum heat sinks reign supreme. Their exceptional thermal conductivity ensures efficient dissipation of heat from electronic components. However, the journey to unlocking their full potential lies in anodizing”an electrochemical process that transforms their surface.

Anodizing Aluminum Heat Sinks: A Paradigm Shift

Anodizing bathes aluminum heat sinks in an electrolyte solution, triggering an electrochemical reaction that creates a protective oxide layer on their surface. This layer, formed from the parent aluminum, boasts remarkable properties that elevate the heat sink’s performance to new heights.

Improved Heat Dissipation: The porous nature of the anodized layer enhances its surface area, providing more channels for heat to escape. This increased surface area also promotes thermal convection, further augmenting heat transfer.

Enhanced Corrosion Resistance: Anodizing creates a protective barrier that shields the aluminum heat sink from environmental factors such as moisture, salts, and acids. This barrier prevents corrosion and ensures the long-term integrity of the heat sink.

Increased Wear Resistance: The oxide layer formed during anodizing imparts enhanced hardness and abrasion resistance to the aluminum heat sink. This increased durability protects it from mechanical damage and extends its operational lifespan.

Electrical Insulation: Anodizing provides electrical insulation between the heat sink and the electronic components it contacts. This prevents electrical shorts and ensures that the heat sink does not interfere with the functioning of the electronic circuit.

Aesthetic Enhancements: Anodized aluminum heat sinks can be customized in a wide range of colors and textures. This allows for aesthetic integration with the surrounding system, enhancing its overall visual appeal.

Unlocking the Potential: Applications and Advantages

Anodized aluminum heat sinks find wide application in various industries, including electronics, automotive, aerospace, and renewable energy. Their superior performance and durability make them a compelling choice for applications requiring efficient heat management.

In conclusion, anodizing aluminum heat sinks is a transformative process that unlocks their full potential. By creating a protective and functional oxide layer, anodizing enhances heat dissipation, corrosion resistance, wear resistance, electrical insulation, and aesthetic appeal. These attributes make anodized aluminum heat sinks an indispensable tool in the field of thermal management, ensuring the reliable and efficient operation of electronic components.