The Impact of Extruded Aluminum Tubes on Modern Engineering: A Transforming Force in Structural Integrity and Innovation

In the realm of engineering, where the pursuit of innovation and durability intertwine, extruded aluminum tubes have emerged as a transformative force, revolutionizing the way we design and construct structures. Their unparalleled properties have propelled them to the forefront of modern engineering, reshaping industries and empowering groundbreaking designs.

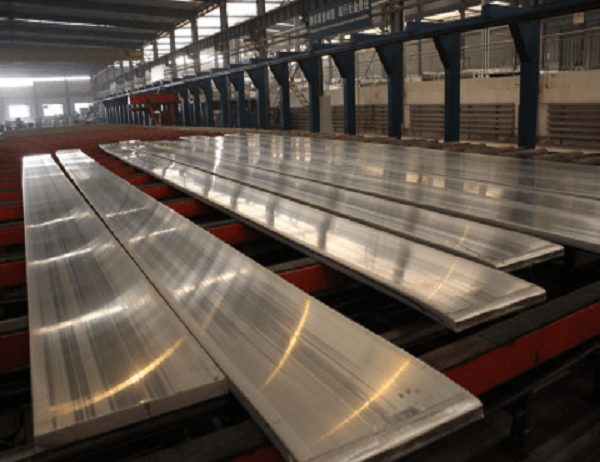

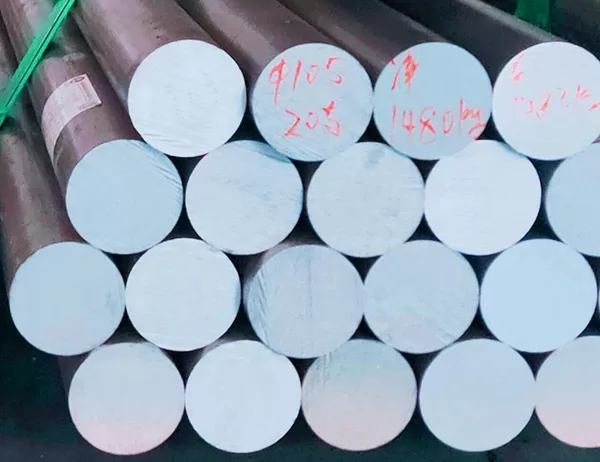

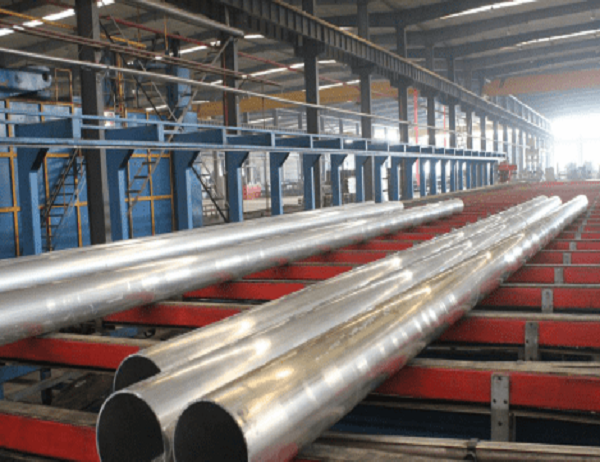

Extruded aluminum tubes are crafted by forcing molten aluminum through a precisely shaped die, creating seamless tubes with consistent dimensions and exceptional strength. This unique manufacturing process imparts a remarkable combination of lightweightness, rigidity, and corrosion resistance. As a result, these tubes have become the preferred choice for a vast array of applications, ranging from structural frameworks to aircraft components.

In the automotive industry, extruded aluminum tubes have played a pivotal role in reducing vehicle weight while enhancing crashworthiness. Their lightweight design allows for improved fuel efficiency and handling, while their robust nature ensures the integrity of the chassis during collisions. Similarly, in the aerospace sector, extruded aluminum tubes have been instrumental in reducing the weight of aircraft, enabling them to fly longer distances and consume less fuel.

Beyond their structural applications, extruded aluminum tubes have also made significant contributions to the electronics and medical fields. In electronic devices, they provide lightweight yet durable enclosures that protect sensitive components. In the medical industry, they are used in surgical instruments and implants due to their biocompatibility and resistance to corrosion.

One striking example of the transformative impact of extruded aluminum tubes is the Burj Khalifa, the world’s tallest building. Its sleek exterior features a complex network of extruded aluminum tubes that contribute to its structural stability and iconic appearance. The use of aluminum tubes allowed the building to reach unprecedented heights while maintaining its architectural integrity.

Extruded aluminum tubes continue to push the boundaries of engineering design, enabling the creation of innovative structures and products. Their versatility, strength, and lightweight nature make them indispensable materials for modern engineers, empowering them to envision and realize daring new feats. As technology advances and new applications emerge, the impact of extruded aluminum tubes on the engineering landscape will only continue to grow, shaping the future of construction and innovation.