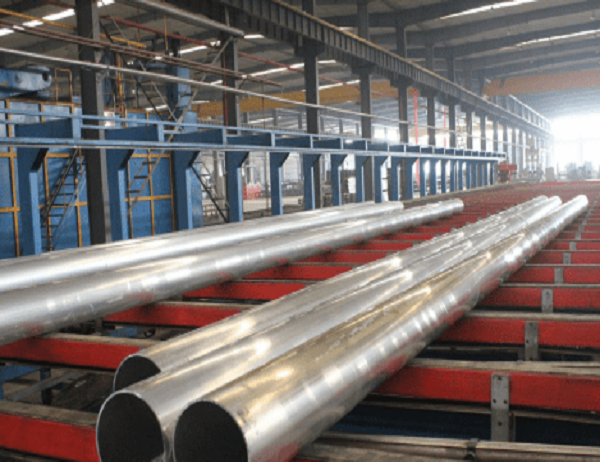

Aluminium tubes are essential components in various industries, ranging from construction to aerospace. Their versatility, strength, and lightweight nature make them the preferred choice for a wide array of applications. As a result, the demand for high-quality aluminium tubes has increased significantly in recent years. To ensure the reliability and safety of aluminium tubes, certification and standards play a crucial role.

Certification and standards provide a framework for aluminium tube suppliers to demonstrate the quality of their products. By adhering to rigorous testing and inspection protocols, suppliers can ensure that their tubes meet industry standards and customer specifications. This ensures that the tubes are free from defects, meet the required dimensions, and possess the necessary mechanical properties for the intended applications.

Aluminium tubes are often used in critical applications, where failure can have severe consequences. Certification and standards establish safety requirements that suppliers must comply with to minimize risks. This includes meeting regulations on chemical composition, surface treatment, and corrosion resistance to safeguard the health and well-being of users and the environment.

Increasingly, customers are demanding aluminium tubes that are produced in an environmentally responsible manner. Certification and standards promote sustainable practices by encouraging suppliers to reduce waste, minimize energy consumption, and use environmentally friendly materials. This ensures that aluminium tubes meet environmental regulations and contribute to a greener future.

Certification and standards facilitate traceability throughout the aluminium tube supply chain. Suppliers need to maintain detailed records of the raw materials used, manufacturing processes employed, and testing results obtained. This traceability allows manufacturers and consumers to verify the origin and quality of the tubes, ensuring accountability and reducing the risk of counterfeiting.

Aluminium tubes are often traded internationally, making global harmonization of certification and standards essential. International standards ensure that products meet the requirements of different markets and reduce trade barriers. By adhering to common standards, aluminium tube suppliers can expand their reach and compete in a global marketplace with confidence.

Certification and standards are indispensable for aluminium tube suppliers to establish trust, ensure quality, prioritize safety, protect the environment, and facilitate global trade. By adhering to rigorous protocols, suppliers can demonstrate the reliability of their products, protect consumers and the environment, and enhance their competitiveness in a demanding global market.