Aluminium track profiles have become increasingly popular in industrial settings due to their exceptional strength, durability, and versatility. These profiles are engineered to withstand demanding conditions, ensuring reliable performance and longevity in various industrial applications. This article explores the strength and durability of aluminium track profiles in industrial environments, highlighting their key advantages and applications.

One of the most significant advantages of aluminium track profiles is their high strength-to-weight ratio. Aluminium alloys used in track profiles possess remarkable strength and stiffness, allowing them to تحمل heavy loads without excessive deflection. This strength-to-weight advantage makes aluminium track profiles ideal for applications where weight reduction is crucial, such as overhead conveyors and lifting systems.

Aluminium is highly resistant to corrosion, making it an excellent material for industrial environments often exposed to harsh chemicals, moisture, and extreme temperatures. The protective oxide layer that naturally forms on the surface of aluminium prevents oxidation and degradation, ensuring long-term durability even in demanding conditions. This corrosion resistance eliminates the need for frequent maintenance and protects against premature failure, reducing downtime and maintenance costs.

Aluminium track profiles have a low coefficient of thermal expansion, which means they undergo minimal dimensional changes due to temperature fluctuations. This stability is critical in industrial applications where precise alignment and dimensional accuracy are essential. Aluminium track profiles maintain their shape and dimensions even under extreme temperature variations, preventing thermal distortions that could affect system performance and safety.

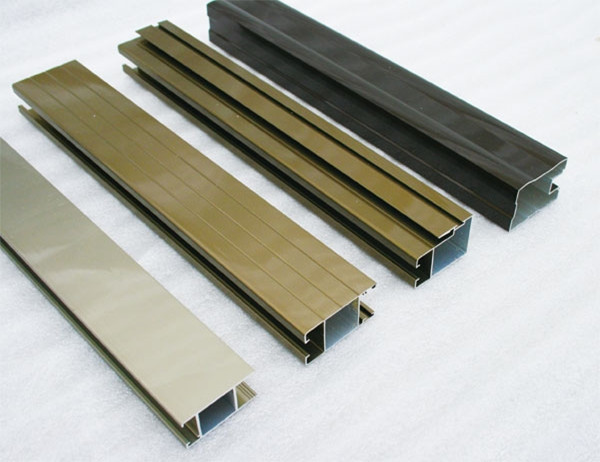

Aluminium track profiles are designed to resist wear and abrasion, ensuring long-lasting performance in harsh environments. The hard anodized surface of aluminium profiles provides excellent wear resistance, protecting against damage caused by friction and contact with abrasive materials. This durability extends the lifespan of track profiles, reducing the need for frequent replacements and minimizing downtime for maintenance.

The strength, durability, and versatility of aluminium track profiles make them suitable for a wide range of industrial applications. They are commonly used in:

Overhead conveyors: Their high strength-to-weight ratio and corrosion resistance make them ideal for transporting heavy loads in overhead conveyor systems.

Machine frames: Aluminium track profiles provide rigid and durable support structures for various industrial machinery and equipment.

Workstations: Their ability to withstand heavy loads and resist wear makes them suitable for industrial workstations, providing a stable and reliable work surface.

Lifting systems: The combination of strength and low weight of aluminium track profiles makes them ideal for lifting and positioning systems, ensuring precise and safe operation.

Aluminium track profiles offer exceptional strength, durability, and versatility, making them an ideal choice for demanding industrial settings. Their high strength-to-weight ratio, corrosion resistance, low coefficient of thermal expansion, wear resistance, and versatility provide reliable performance and longevity in a wide range of applications. By utilizing aluminium track profiles, industries can enhance the efficiency, safety, and lifespan of their operations, leading to increased productivity and reduced downtime.