The Ultimate Guide to Aluminum Track Profiles: A Comprehensive Reference for Professionals

Are you an engineer, architect, or designer involved in projects that require aluminum track profiles? The Ultimate Guide to Aluminum Track Profiles is an invaluable resource, providing extensive knowledge and practical insights into this essential building component. Explore the definitive guide to deepen your understanding and optimize your designs.

Design Considerations for Aluminum Track Profiles

When selecting aluminum track profiles, several design considerations come into play:

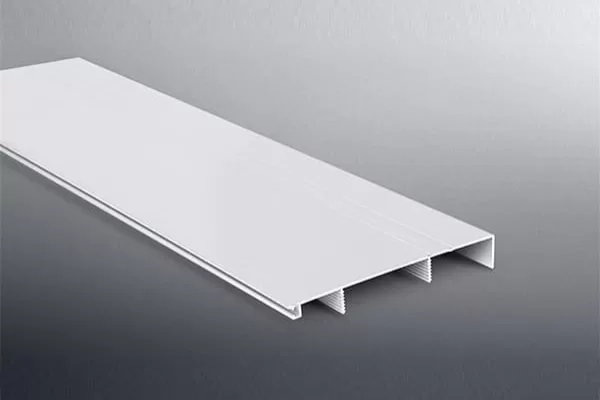

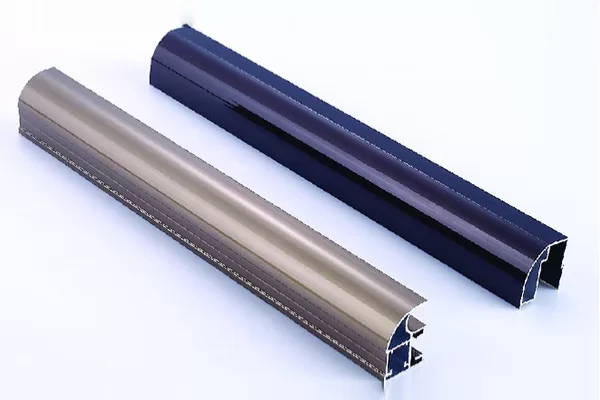

– Profile Shape: Track profiles come in various shapes, from U-shaped and C-shaped to complex geometries. The shape determines their load-bearing capacity, compatibility with accessories, and aesthetic appeal.

– Material Grade: The grade of aluminum used influences the strength, corrosion resistance, and durability of the profile. Understanding the different grades and their properties is crucial for choosing the appropriate profile.

– Surface Finish: Aluminum track profiles can be finished with treatments like anodizing or powder coating, enhancing their corrosion resistance, wear resistance, and appearance. Choose a finish that aligns with the project’s requirements and aesthetic considerations.

Applications of Aluminum Track Profiles

Aluminum track profiles find applications in a diverse range of industries, including:

– Construction: As support structures for walls, ceilings, and lighting fixtures in commercial and residential buildings

– Industrial: For conveyor systems, machinery guards, and workspace partitions in manufacturing facilities

– Transport: In vehicle frames, interior fittings, and cargo handling systems in the transportation sector

– Retail: For display shelves, point-of-sale systems, and signage in retail environments

Installation Techniques for Aluminum Track Profiles

Proper installation is essential to ensure the longevity and performance of aluminum track profiles. The guide covers various installation techniques, including:

– Mounting Options: Explore different mounting methods, such as surface mounting, recessed mounting, and concealed mounting

– Fastening Methods: Learn about various fastening options like screws, bolts, and rivets, ensuring secure attachment

– Splicing Techniques: Understand how to seamlessly join aluminum track profiles to create longer or more complex structures

Maintenance and Inspection of Aluminum Track Profiles

Regular maintenance and inspection are crucial to maintain the integrity and functionality of aluminum track profiles. The guide provides insights on:

– Inspection Procedures: Identify signs of corrosion, damage, or wear that may require attention or repair

– Cleaning and Maintenance: Outline best practices for cleaning and maintaining the profiles to prevent premature deterioration

– Repair Techniques: Explore techniques for repairing minor damages, ensuring the profiles remain in optimal condition

Industry Standards and Regulations

The Ultimate Guide to Aluminum Track Profiles also delves into industry standards and regulations related to their use. This knowledge enables designers and engineers to meet legal and performance requirements, ensuring safety and compliance.

Conclusion

The Ultimate Guide to Aluminum Track Profiles empowers professionals with comprehensive knowledge and practical guidance on designing, specifying, installing, and maintaining these versatile building components. By delving into the details of aluminum track profiles, readers gain a competitive edge and deliver innovative and functional solutions in a wide range of industries. Whether you are an experienced professional seeking to enhance your expertise or a newcomer eager to gain a thorough understanding, this guide is an indispensable resource for unlocking the full potential of aluminum track profiles.