The Ultimate Guide to Extruded Aluminum Tubes: An In-Depth Exploration of Their Applications and Benefits

“The Ultimate Guide to Extruded Aluminum Tubes” is a comprehensive resource that delves into the myriad uses and advantages of extruded aluminum tubes, making it an invaluable tool for engineers, designers, and industry professionals alike. This guide thoroughly examines the properties, fabrication methods, and applications of extruded aluminum tubes, providing a comprehensive understanding of this versatile material.

Properties of Extruded Aluminum Tubes

Strength and Durability

Extruded aluminum tubes possess exceptional strength and durability, making them ideal for demanding applications. Aluminum’s strength-to-weight ratio allows for lightweight yet robust structures, while its natural corrosion resistance ensures long-term performance even in harsh environments.

Precision and Tolerances

Extrusion technology enables the production of aluminum tubes with precise dimensions and tolerances, allowing for seamless integration into complex assemblies. This precision eliminates the need for additional machining, reducing production costs and improving product quality.

Fabrication Methods

Extrusion Process

The extrusion process involves forcing molten aluminum through a die to obtain the desired tube shape. This method allows for intricate designs and complex geometries, resulting in tubes with consistent cross-sections and smooth finishes.

Post-Extrusion Treatments

Post-extrusion treatments, such as annealing, quenching, and aging, can enhance the mechanical properties of extruded aluminum tubes. These treatments alter the microstructure of the material, improving strength, ductility, and corrosion resistance.

Applications of Extruded Aluminum Tubes

Automotive Industry

Extruded aluminum tubes are widely used in the automotive industry for structural components, such as pillars, door frames, and bumper reinforcements. Their lightweight and high strength contribute to improved vehicle performance and fuel efficiency.

Aerospace Engineering

In aerospace engineering, extruded aluminum tubes serve as lightweight and reliable structural supports for aircraft fuselages, wings, and landing gear. Their ability to withstand high stresses and maintain structural integrity makes them essential for aircraft safety.

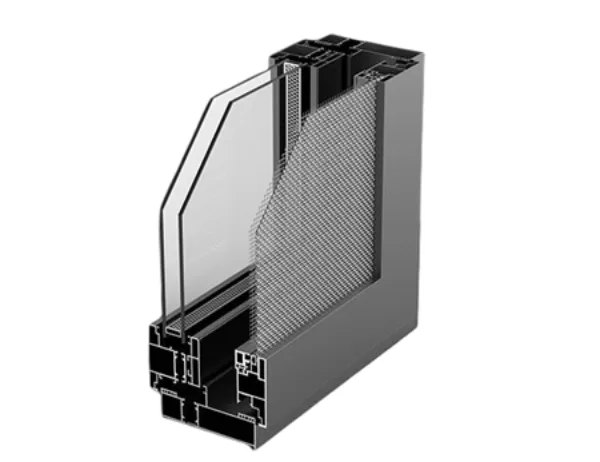

Construction and Architecture

Extruded aluminum tubes play a significant role in construction and architecture, particularly in curtain walls, windows, and structural framing. Their corrosion resistance and aesthetic appeal enhance the durability and appearance of modern buildings.

Medical Devices

Extruded aluminum tubes find application in medical devices, such as surgical implants, prosthetics, and diagnostic equipment. Their biocompatibility, high strength, and ability to be sterilized make them ideal for use in demanding medical environments.

Benefits of Extruded Aluminum Tubes

Sustainability

Aluminum is a highly recyclable material, and extruded aluminum tubes contribute to sustainability by reducing waste and conserving natural resources. Recycling aluminum requires only a fraction of the energy needed to produce new metal, promoting environmental stewardship.

Versatility

Extruded aluminum tubes can be customized to meet specific requirements, making them suitable for a wide range of applications. Their ability to be anodized, colored, or painted further enhances their versatility and aesthetic appeal.

Cost-Effectiveness

Despite their exceptional properties, extruded aluminum tubes offer cost-effective solutions compared to other materials. Their lightweight nature and efficient fabrication methods reduce transportation and production costs, making them an economical choice.