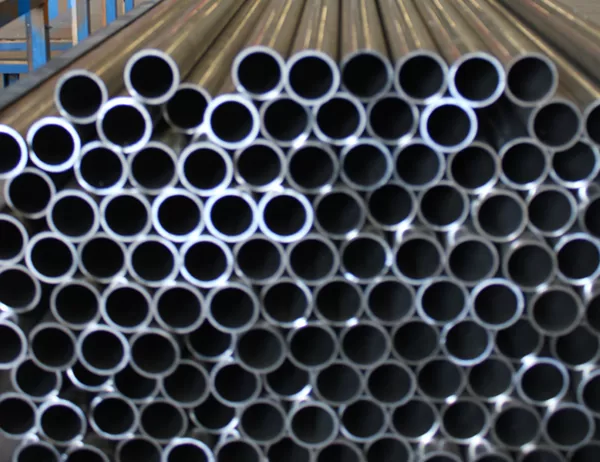

Aluminum profiles have become ubiquitous in industrial applications due to their exceptional combination of strength, lightness, and corrosion resistance. Understanding the technology behind these profiles is essential for maximizing their benefits and ensuring optimal performance in demanding environments. This article delves into the intricacies of industrial aluminum profiles, exploring various aspects that contribute to their unique capabilities.

Material Properties and Alloy Selection

The properties of aluminum profiles are largely determined by their alloy composition. Common alloys used for industrial applications include 6061, 6063, and 6082. These alloys offer a balance of strength, ductility, and corrosion resistance, making them suitable for various structural and architectural purposes.

Extrusion Process

Extrusion is the primary method used to shape industrial aluminum profiles. In this process, molten aluminum is forced through a die, creating a continuous profile with the desired cross-sectional shape. The extrusion temperature, die design, and extrusion speed all have a significant impact on the final properties and dimensional accuracy of the profiles.

Surface Treatment and Coatings

Industrial aluminum profiles can undergo various surface treatments to enhance their durability and aesthetic appeal. Anodizing, for instance, creates a protective oxide layer on the aluminum surface, improving corrosion resistance and wear resistance. Powder coating, on the other hand, provides a colorful and durable finish that can protect the profiles from scratches and chemicals.

Customization and Applications

Industrial aluminum profiles can be customized to meet specific application requirements. This includes varying the alloy composition, profile dimensions, and surface treatment to suit different load-bearing capacities, corrosion resistance levels, and aesthetic preferences. They are widely used in construction, machinery, transportation, and energy industries, among others.

Quality Standards and Testing

To ensure the reliability and performance of industrial aluminum profiles, they are subjected to rigorous testing and certification processes. These tests evaluate the mechanical properties, corrosion resistance, and dimensional accuracy of the profiles to meet industry standards.

Advantages of Industrial Aluminum Profiles

Strength and Lightweight: Aluminum profiles offer a high strength-to-weight ratio, making them suitable for load-bearing applications while reducing overall weight.

Corrosion Resistance: The innate corrosion resistance of aluminum and the protective surface treatments enhance the profiles’ durability in harsh environments.

Versatility: Industrial aluminum profiles can be customized to meet diverse application requirements, enabling their use in a wide range of industries.

Sustainability: Aluminum is a recyclable material, making the manufacturing and disposal of profiles environmentally friendly.