Rising demand for durable, lightweight materials in construction and manufacturing has brought aluminum to the forefront of innovation. Among the most commonly used components is the 100mm aluminium tube, known for its strength, corrosion resistance, and adaptability across sectors. From heavy-duty frames to structural supports and precision-engineered equipment, these tubes are an integral part of industrial infrastructure.

A 100mm aluminium tube offers excellent load-bearing capacity while maintaining a relatively low weight. Its uniform surface and inner diameter make it suitable for high-precision applications, including automation systems, modular structures, and energy installations. The increasing preference for recyclable and sustainable materials further strengthens aluminum’s position in global supply chains.

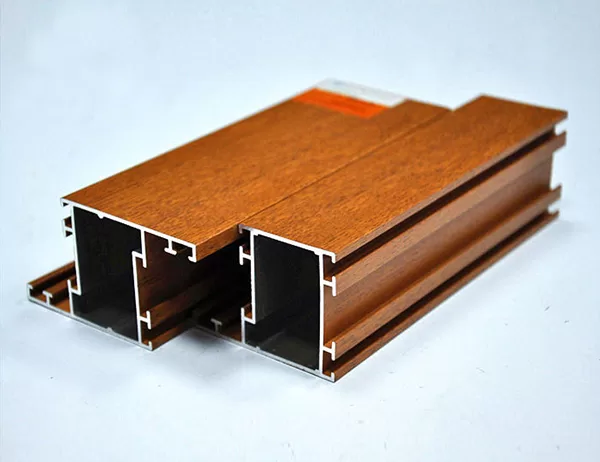

For customized shapes and applications, working with a reliable aluminum section manufacturer ensures that every specification is met with consistency and technical accuracy. These manufacturers specialize in producing extruded aluminum components using advanced tooling systems and quality-controlled production environments. They provide a wide range of profiles, including angles, channels, tubes, and complex cross-sections for architectural or mechanical use.

Customers seeking scalability and product variety often rely on experienced aluminum profile suppliers. These suppliers maintain an extensive inventory of ready-made and bespoke profiles tailored to meet the demands of industries such as automotive, aerospace, electronics, furniture, and construction. Many suppliers also offer additional services such as anodizing, powder coating, and CNC machining to enhance product functionality and aesthetics.

By sourcing from trusted aluminum profile suppliers, businesses benefit from fast lead times, dependable quality assurance, and technical support throughout the procurement process. High-tolerance extrusions allow for seamless integration into existing systems and reduce material waste during installation.

The aluminum market continues to grow due to increased investment in infrastructure, transportation, and renewable energy. Lightweight aluminum tubes and sections offer design flexibility while meeting high safety and performance standards. The 100mm aluminium tube, for example, remains a popular choice in both commercial and industrial projects where size, durability, and corrosion resistance are critical.

An efficient supply chain starts with choosing an aluminum section manufacturer that values innovation, material traceability, and international standards compliance. When paired with experienced suppliers, the result is a streamlined sourcing process that reduces costs and improves end-user satisfaction.

Modern engineering depends on reliable materials. Whether for a large-scale construction site or a high-precision assembly, aluminum profiles deliver the strength and longevity required in today’s competitive markets.