When selecting materials for architectural projects, architects and designers face a wide range of choices. Among the most popular options is white powder coated aluminum, a versatile material offering numerous advantages over other finishes. This comparative analysis delves into the key aspects that differentiate white powder coated aluminum from alternative finishes, providing valuable insights for informed decision-making.

Durability

Superior Corrosion Resistance

White powder coated aluminum exhibits exceptional corrosion resistance due to its protective oxide layer. This coating shields the aluminum from environmental elements such as moisture, acids, and salt, preventing premature degradation. In contrast, finishes like liquid paint or anodized aluminum are more susceptible to corrosion, requiring frequent maintenance and repairs.

Resistance to UV Rays

White powder coating provides excellent resistance to UV radiation, preventing yellowing and fading over time. This is crucial for outdoor applications where finishes are exposed to prolonged sunlight. Other finishes, such as acrylic paint or vinyl, can rapidly deteriorate under UV exposure, compromising their aesthetics and longevity.

Aesthetics

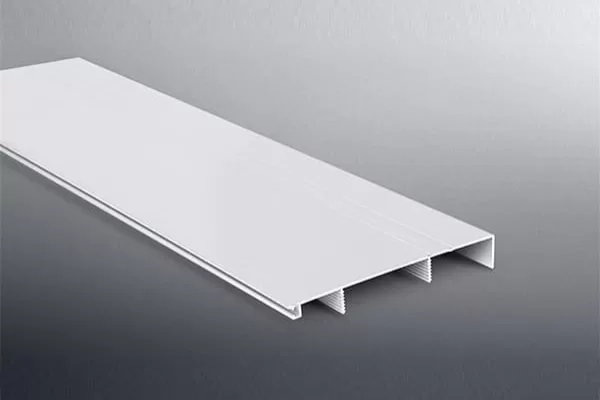

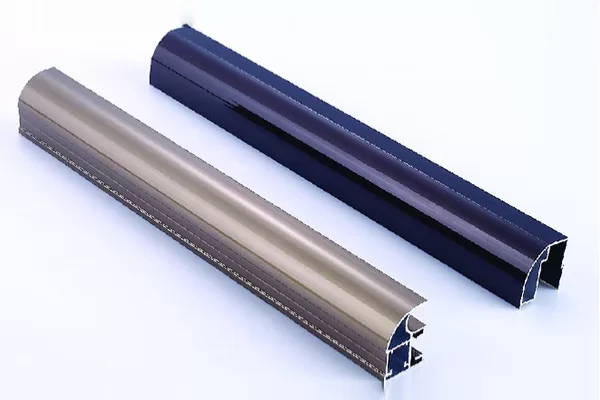

Uniform Color and Texture

Powder coating produces a uniform color and texture, ensuring a consistent and seamless finish. The electrostatic application process creates an even distribution of the coating, eliminating the risk of brush strokes or color variations found in liquid paint. This consistency is particularly advantageous for large-scale projects where a uniform appearance is essential.

Matte or Gloss Finish Options

White powder coating offers customizable finish options, ranging from matte to high-gloss. Matte finishes provide a subtle, sophisticated look, while high-gloss finishes reflect light, creating a more vibrant and reflective appearance. This versatility allows designers to tailor the finish to match the desired aesthetic of the project.

Maintenance and Cleaning

Low Maintenance Requirements

White powder coated aluminum requires minimal maintenance. Its non-porous surface resists dirt, grime, and graffiti, reducing the need for frequent cleaning. Unlike liquid paint, powder coating does not chip or peel, eliminating the need for repainting or touch-ups.

Easy Cleaning

Cleaning white powder coated aluminum is easy and efficient. Mild soap and water are typically sufficient for removing dirt and stains. Abrasive cleaners should be avoided, as they can damage the finish. The low-maintenance nature of powder coating significantly reduces the overall cost of ownership compared to other finishes.

Environmental Sustainability

Reduced VOC Emissions

White powder coating has a lower environmental impact than other finishes. The process emits minimal volatile organic compounds (VOCs), contributing to improved indoor air quality and reducing the risk of air pollution. In contrast, liquid paint finishes release significant amounts of VOCs, posing potential health hazards and environmental concerns.

Recyclable Material

Aluminum is a recyclable material, making powder coated aluminum environmentally friendly. This allows for the efficient disposal and reuse of the material at the end of its lifespan, promoting sustainable construction practices. Other finishes, such as PVC, are not as readily recyclable, adding to landfill waste.

Conclusion

White powder coated aluminum stands out as a superior choice among architectural finishes, offering unmatched durability, aesthetics, low maintenance, and environmental sustainability. Its exceptional corrosion resistance, UV protection, uniform appearance, customizable finish options, and easy cleaning make it an ideal choice for demanding projects. Furthermore, its low VOC emissions and recyclability align with environmental best practices. By understanding the advantages of white powder coated aluminum, architects and designers can make informed decisions that enhance the longevity, aesthetics, and overall value of their projects.