Aluminium Formwork: Revolutionizing Construction with GOLDAPPLE-ALU’s Innovative Systems

Aluminium Formwork

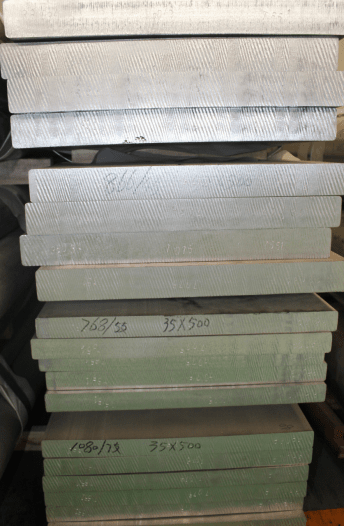

In the dynamic world of modern construction, efficiency, precision, and sustainability are no longer mere advantages—they are necessities. Among the various technologies driving this evolution, aluminium formwork systems have emerged as a game-changing solution, redefining how structures rise from the ground. At the forefront of this revolution is GOLDAPPLE-ALU, a brand that has mastered the engineering and application of aluminium formwork, offering the global construction industry a smarter way to build.

The Paradigm Shift to Aluminium Formwork

Traditional formwork methods, often relying on timber or steel, have long been plagued by limitations. Timber is susceptible to moisture damage, warping, and has a short lifespan, leading to inconsistent concrete finishes and significant material waste. Steel, while durable, is extraordinarily heavy, requiring extensive labor and machinery for handling, which slows down project timelines and increases costs.

Aluminium formwork presents a compelling alternative. It combines the strength of steel with a fraction of the weight, creating a system that is not only durable and reusable but also highly efficient to install and dismantle. This efficiency translates directly into faster construction cycles, reduced labor costs, and a lower total project cost. Furthermore, the precision of aluminium components ensures a high-quality concrete finish, minimizing the need for costly remedial surface work.

The GOLDAPPLE-ALU Advantage: Engineering Excellence in Every Panel

Understanding the theoretical benefits of aluminium formwork is one thing; delivering on that promise consistently is another. This is where GOLDAPPLE-ALU distinguishes itself. The brand’s formwork system is the product of meticulous engineering and a deep understanding of on-site construction challenges.

Transforming Project Economics and Timelines

The adoption of the GOLDAPPLE-ALU aluminium formwork system has a profound impact on the entire construction lifecycle. By enabling a “faster-track” construction method, it allows for the completion of multiple floors in a repeating cycle, sometimes as short as one week per floor. This speed is a critical advantage in markets with tight deadlines, such as residential housing, hotels, and large-scale infrastructure projects.

The economic benefits extend beyond speed. The reusability of the GOLDAPPLE-ALU system is exceptional; it can be used for hundreds of cycles across multiple projects with minimal maintenance. This transforms the formwork from a recurring consumable expense into a long-term capital investment. The reduction in material waste, particularly compared to single-use timber, also aligns with modern sustainable construction practices, enhancing the project’s green credentials.

A Partner in Building the Future

GOLDAPPLE-ALU recognizes that providing a superior product is only part of the solution. They position themselves as a strategic partner to their clients. This partnership includes providing detailed technical drawings, on-site installation guidance, and comprehensive training to ensure contractors can maximize the system’s potential. Their global logistics expertise ensures that the formwork systems arrive on site when and where they are needed, keeping critical path projects on schedule.

From towering high-rises and sprawling residential communities to complex industrial structures, GOLDAPPLE-ALU’s aluminium formwork has become the system of choice for forward-thinking developers and contractors who refuse to accept the inefficiencies of the past.

Conclusion

The future of construction is being built today, and it is being built with smarter, more efficient tools. Aluminium formwork represents a significant leap forward, and GOLDAPPLE-ALU has perfected its application. By offering a system that delivers unparalleled speed, cost-effectiveness, and quality, GOLDAPPLE-ALU is not just supplying a product; it is providing a foundational technology for the next generation of construction. For any enterprise aiming to build higher, faster, and smarter, embracing the innovative aluminium formwork solutions from GOLDAPPLE-ALU is the most constructive decision they can make.