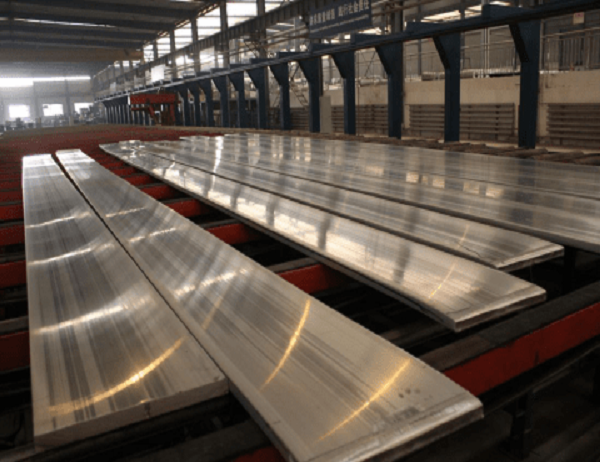

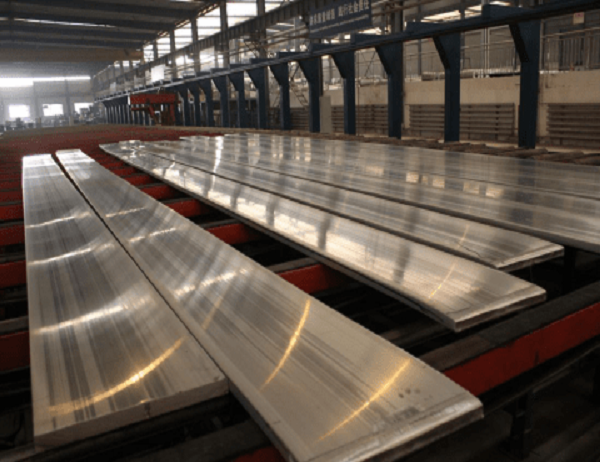

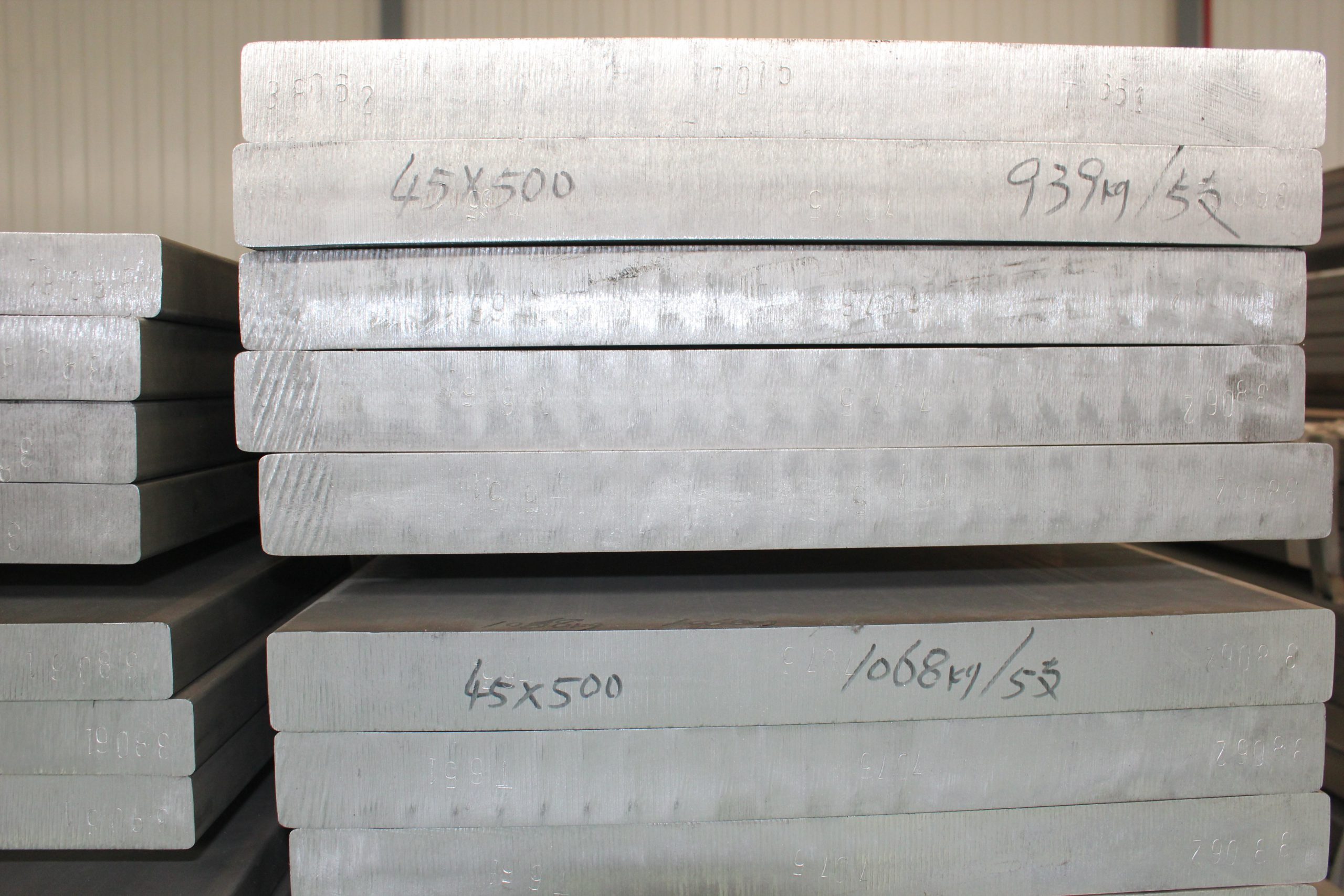

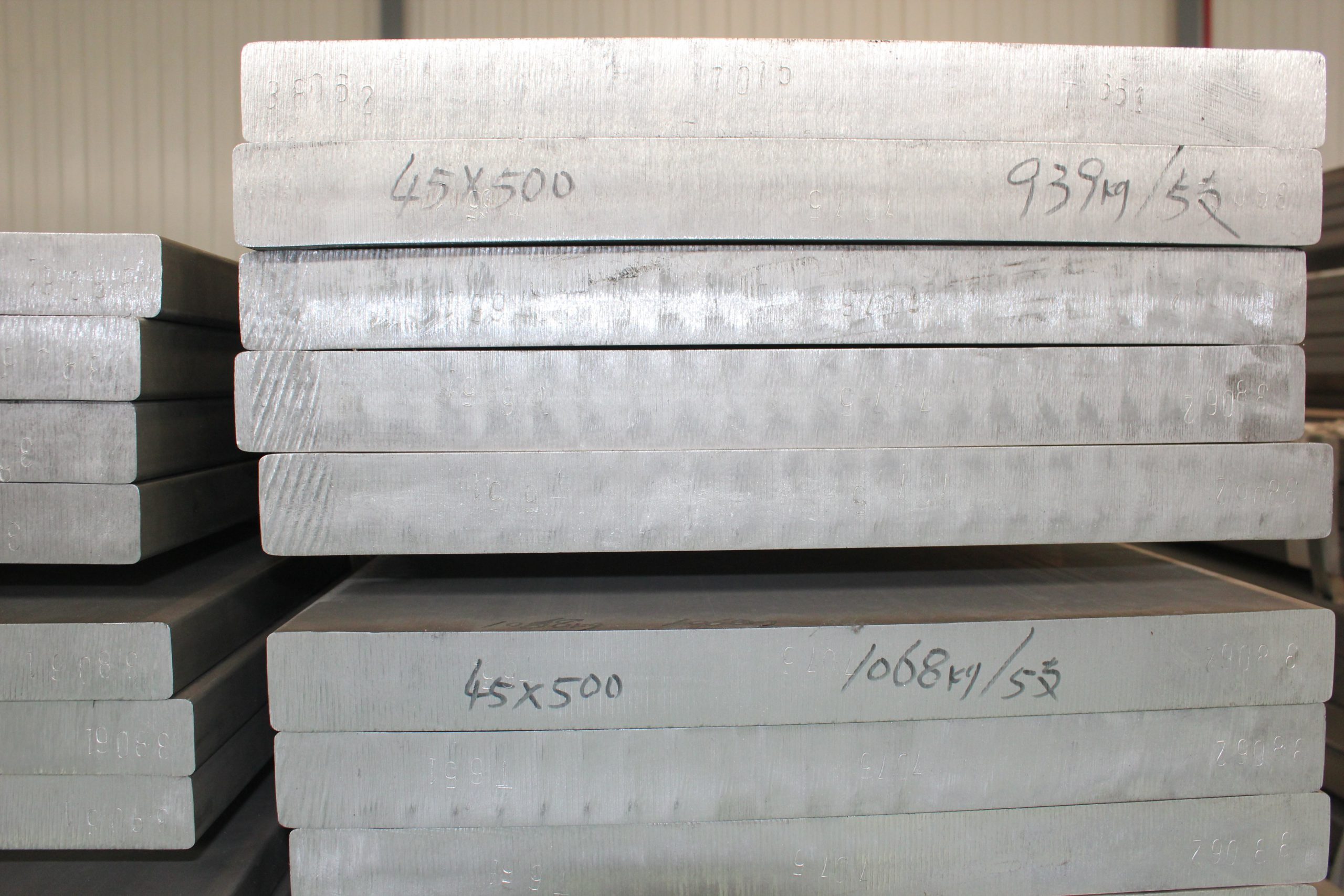

Aluminium Sheet And Strip Material

Product Details

Product introduction:

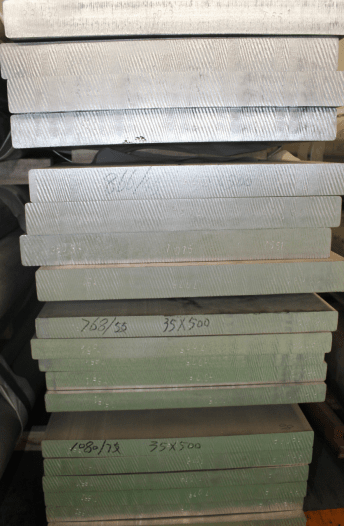

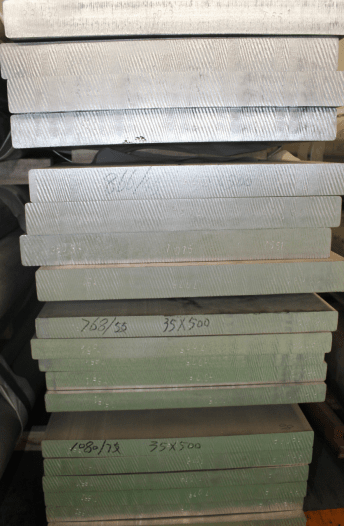

The company's existing 13 production lines can produce 1-7 series aluminum alloy sheet and strip material with a thickness greater than 10mm and a width less than 500mm, of which the dimensional accuracy, surface quality and mechanical properties of the 6 series aluminium alloy sheet and strip produced by the extruder under 36MN can meet the use; especially the 7075 alloy aluminum sheet and strip material with 500mm width produced by the 100MN extruder, its mechanical properties and hardness are much higher than the national standard value.

Application:

Scope of application: Aluminum alloy sheet and strip material is mainly used in automotive, medical and other industries. It‘s widely used.

The 1 series to 7 series that our company can produce are as follows:

Temper: H112 T4 T6 T651 Alloy: 1 series to 7 series Length: 7m-14m product diameter:100mm-500mm Wall thickness:Over 10mm

Package:

Bare package;

waterproof cloth / plastic film wrapping, steel band bundling, wooden pallet bottom;

cube packaging, wooden pallet bottom, steel band bundling

Product Advantages

1. Sophisticated production technology, advanced equipment. The main production equipment and testing equipment are imported from abroad

2. High precision, high strength, corrosion resistance and wear resistance

3. The technical center (central laboratory) has been assessed as the Qinghai Engineering Technology Center. It is not only capable of analyzing the chemical composition of the aluminum alloy tube and rod production, metallurgical structure inspection, and mechanical property testing, but also can meet the needs of new product and new process development.

4. Certificates to prove quality:

01 Weaponry equipment research and production license

02 National Industrial Production License

03 Quality management system certification

04 Environmental management system certification

05 Occupational health and safety management system certification

Shipment:

Standard loading quantity:

1*20GP:Max .length:5.85 meters Loaded quantity: 10 to 12 tons

1*40HQ:Max. length:12 meters Loaded quantity: 22-26 tons

Standard export port:

Huangpu/ Foshan or Shenzhen

Type of shipping:

Shipment by sea; by road; by train; multi-transportation.

Knowledge

Pingguo Jianfeng Aluminum Co., Ltd. is among the best aluminum extrusion suppliers in China that supply and export various Chinese aluminum extrusions to international markets and clients. They make different types of aluminum profiles to cater different needs.

With construction being a high profiled industry, there has been a large demand for aluminum profiles to build homes, commercial buildings, machinery, furniture, and so many other things. These aluminum profiles are used in windows, doors, curtain walls, and architectural interiors of many homes. Aluminum profiles have been a hot trend lately because it is being used in different applications of machinery making.

As a recognized aluminum extrusion supplier, the company makes different types of aluminum profiles. The company produces 7 series of aluminum profiles. All of them are high-precision, high-strength, and corrosion-resistant. Some of them are aluminum alloy pipes and rod profiles that have specific wear-resistant to make them last longer. These alloy pipes and rod profiles are not your everyday Chinese aluminum extrusions because aluminum extrusion suppliers offer these to be used in heavy industries such as aviation, aerospace, military industry, petroleum, energy, and natural gas industry.

Seamless Pipe: The seamless pipes have a model no. H112 T4 T6. Their grade is 3000 series. These pipes are used in the petroleum industry, chemical industry, and high-pressure containers. These seamless pipes have the certification of ISO9001, ISO14000, and ISO10012.

1. Series Aluminum Alloy Extrusion: Gold Apple model number 1060 is given to grade 1000 series of Aluminum alloy extrusion profiles. These are 100 % made with alloy material with a thickness of 1.0mm. This type of Chinese aluminum extrusions offer good electrical conductivity, welding performance but low strength. It is good for chemical and scientific experiments.

2. Series Aluminum Alloy Extrusion: Gold Apple, a grade 2000 series comes with multiple ISO certifications. The model numbers of this series are 2014,2017,2024,2A11,2A12,2A14, 2A5, and 2A70 respectively. The manufacturing of this aluminum profile says it has copper as the main element, manganese, magnesium, and bismuth are also added mechanizability.

3. Series Aluminum Alloy Extrusion: Model Number: 3A21 of 3000 grade is ideal for canning because it is totally corrosion free and perfect for humid environments. It can be used in refrigerators, air conditioning pipes, and car bottom. It has a diameter of 100mm-600mm.

4. Series Aluminum Alloy Extrusion: 4Series aluminum alloy extrusion cannot be heat treated. It is ideal for forging materials, welding materials, mechanical parts, and construction materials. It has a model number 4032.

5. Series Aluminum Alloy Extrusion: 5 Series Aluminum profiles are made with magnesium mainly. Cold processing is ideal to keep its strength. Its main features are low density, high tensile strength, and high elongation. It is used to make conventional handles of various items.

6. Series Aluminum Alloy Extrusion: This one features magnesium and silicon as the main materials. It is used widely for car trunks, windows, doors, and heat sinks.

7. Series Aluminum Alloy Extrusion: It is made with zinc as the main element. It is used in rockets, aviation space crafts, and other hardcore projects.