Aluminium Formwork System: Engineering Excellence with GOLDAPPLE-ALU

Aluminium Formwork System

In contemporary construction, where time efficiency and structural precision are paramount, the aluminium formwork system has emerged as a transformative methodology. This innovative approach to concrete forming represents a significant evolution from traditional timber and steel systems, offering unparalleled advantages in speed, accuracy, and cost-effectiveness. Leading this technological shift is GOLDAPPLE-ALU, a brand that has refined aluminium formwork into a sophisticated construction solution trusted by developers worldwide.

The Fundamental Advantages of Aluminium Formwork Systems

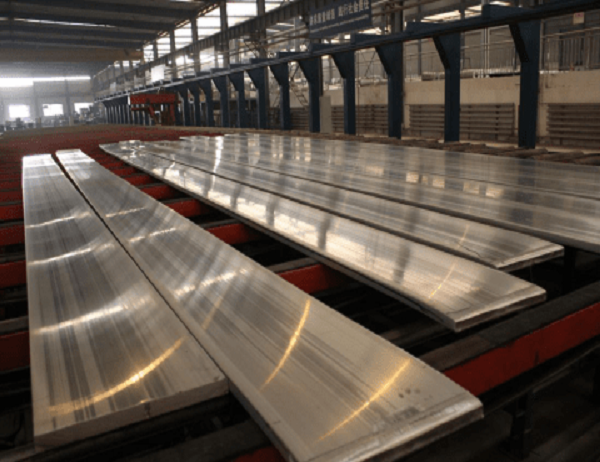

The core principle behind any aluminium formwork system is its modular, lightweight, and high-strength nature. Unlike timber formwork that warps and deteriorates, or heavy steel systems that require crane assistance for nearly every movement, aluminium formwork strikes an ideal balance. Its lightweight panels can be manually handled, dramatically reducing labor time and equipment dependency. Simultaneously, the material’s inherent strength ensures it can withstand the substantial pressures of liquid concrete without deflection, resulting in perfectly flat surfaces and true geometries.

The most significant benefit, however, lies in the system’s reusability and efficiency. A single GOLDAPPLE-ALU aluminium formwork system is engineered for hundreds of reuses across multiple projects. This transforms it from a consumable expense into a long-term investment, drastically reducing the per-use cost and minimizing construction waste. The system facilitates a repetitive cycle construction method, enabling crews to complete a floor in a matter of days, which is revolutionary for large-scale residential, commercial, and institutional projects.

GOLDAPPLE-ALU: A System Designed for Perfection

While many suppliers offer aluminium formwork, the GOLDAPPLE-ALU system is distinguished by its precision engineering and holistic design philosophy. It is not merely a collection of panels but a fully integrated building solution.

Transforming Project Execution and Economics

The implementation of the GOLDAPPLE-ALU aluminium formwork system redefines a project’s critical path. Its modular nature allows for systematic, rapid repetition. As one floor is being concreted, the forms from the floor below are being struck and assembled for the next level above. This streamlined process can reduce overall project timelines by 30% to 50%, a decisive advantage in fast-track development.

Economically, the value proposition is clear. The high reusability spreads the initial investment over a vast number of uses, making it exceptionally cost-effective for multi-unit projects. The reduction in crane time, lower labor requirements, and elimination of plastering contribute significantly to the bottom line. Furthermore, the minimized material waste aligns with global green building standards, enhancing the project’s sustainability profile—a key concern for modern developers and corporations.

A Partnership for Success

GOLDAPPLE-ALU understands that delivering a superior system is only part of the equation. They commit to a true partnership with their clients, providing comprehensive support that includes detailed project-specific drawings, on-site technical assistance during the initial setup, and dedicated training programs. This ensures that construction teams can harness the full potential of the system from day one, maximizing productivity and quality. Their global logistics network guarantees reliable delivery, ensuring that projects never face delays due to material unavailability.

Conclusion: Building the Future, Efficiently

The aluminium formwork system is more than a construction tool; it is a methodology for building smarter, faster, and better. In a competitive global market, adopting this technology is no longer an option but a strategic imperative for growth-oriented construction firms. GOLDAPPLE-ALU stands as the partner of choice in this endeavor, offering a system that embodies engineering excellence, operational efficiency, and enduring value. By choosing the GOLDAPPLE-ALU aluminium formwork system, developers and contractors are not just investing in a product—they are investing in a future where their projects are defined by quality, speed, and intelligent construction.