Aluminum formwork accessories play a vital role in ensuring the efficiency, safety, and quality of concrete formwork systems. These components are designed to enhance the performance and durability of formwork, enabling contractors to achieve precise and cost-effective results. In this article, we will provide comprehensive reviews and recommendations for aluminum formwork accessories, covering various aspects to assist you in making informed decisions.

Aluminum formwork accessories encompass a wide range of components, each serving a specific function. Some of the most common types include:

Form Ties

Form ties are essential for securing opposing formwork panels and maintaining their alignment. They come in various types, such as wedge ties, spring clamps, and snap ties, and are designed to withstand different loads and conditions.

Form Braces

Form braces provide lateral support and stability to formwork, preventing buckling or distortion under concrete pressure. They are available in different lengths and configurations to accommodate various wall heights and concrete loads.

Corner Profiles

Corner profiles are used to create precise and durable corners in formwork. They come in various shapes and sizes to suit different wall angles and provide a smooth transition between formwork panels.

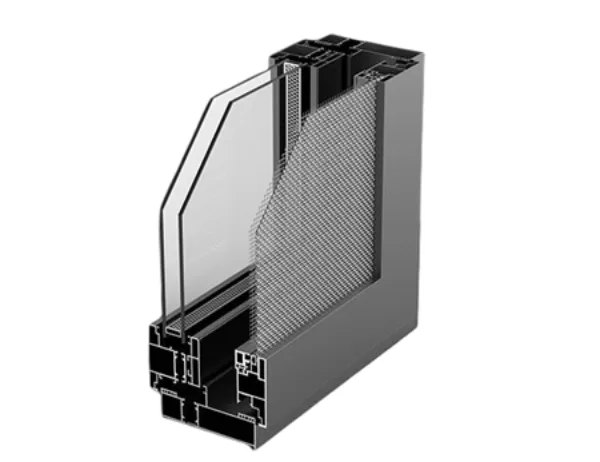

Form Panel Connectors

Form panel connectors are crucial for joining formwork panels together, ensuring a tight and secure fit. They come in different types, such as pin connectors, bolt connectors, and wedge connectors, and are designed to handle various loads and provide flexibility.

Aluminum formwork accessories offer numerous benefits that contribute to the efficiency and success of concrete construction projects:

Durability and Lightweight

Aluminum is known for its exceptional strength and durability, making its accessories highly resistant to damage and wear. Additionally, aluminum’s lightweight nature reduces the weight of formwork systems, facilitating handling and installation.

Corrosion Resistance

Aluminum’s excellent corrosion resistance protects accessories from moisture and chemicals present in concrete environments. This ensures a long lifespan and minimizes maintenance requirements.

Versatile and Adaptable

Aluminum formwork accessories come in a wide range of designs and sizes, providing flexibility and adaptability to suit different project requirements. They can be easily customized to accommodate complex geometries and special applications.

Cost-Effective

Although aluminum is a relatively expensive material, its durability and long lifespan make it a cost-effective investment over the long term. Aluminum formwork accessories can be reused multiple times, reducing material waste and overall project costs.

When selecting aluminum formwork accessories, consider the following recommendations:

Compatibility with Formwork System

Ensure that the accessories are compatible with your specific formwork system. Dimensions, load capacities, and connection methods should align to prevent issues during assembly and operation.

Load Capacity

Select accessories that can handle the anticipated concrete loads and pressure. Consider factors such as wall height, concrete strength, and pouring method to determine the required load-bearing capacity.

Durability and Corrosion Resistance

Opt for accessories made from high-quality aluminum alloys that provide superior durability and corrosion resistance. This will ensure a long lifespan and minimize maintenance costs.

Ease of Use

Choose accessories that are easy to install, adjust, and remove. Consider aspects such as connection mechanisms, alignment features, and the availability of specialized tools.

Aluminum formwork accessories are indispensable components that enhance the performance and efficiency of concrete formwork systems. Understanding the different types, benefits, and selection criteria will empower you to make informed choices that contribute to successful construction projects. By incorporating high-quality aluminum formwork accessories into your operations, you can achieve precision, productivity, and cost-effectiveness in your concrete construction endeavors.