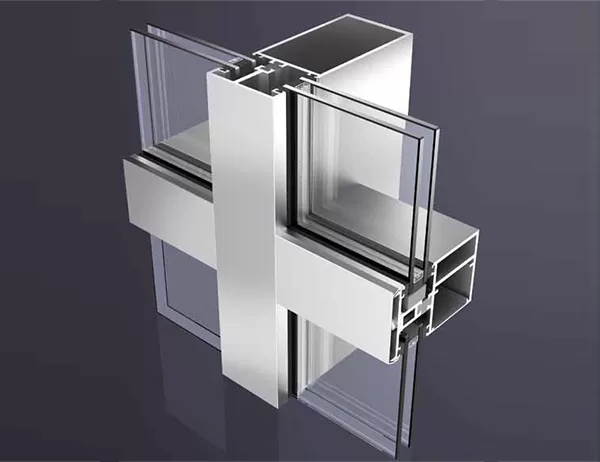

Aluminium is transforming the construction industry with its lightweight strength, corrosion resistance, and design flexibility. For developers, contractors, and engineers, sourcing from trusted aluminium profiles suppliers ensures structural integrity, cost efficiency, and long-term durability. Whether for façade systems, window frames, curtain walls, or temporary construction systems like formwork, high-quality aluminium profiles are essential for modern infrastructure.

Among the most important applications is aluminium formwork, a revolutionary solution in concrete construction. Unlike traditional wood or steel formwork, aluminium formwork is reusable, faster to assemble, and delivers precise casting with minimal waste. Leading aluminium formwork suppliers offer not only standardized panel systems but also custom-designed solutions that fit specific project requirements. This allows for rapid on-site assembly, labor cost savings, and smoother concrete finishes.

Choosing the right aluminium formwork factory goes beyond product specs. Manufacturers with in-house design, extrusion, and surface treatment capabilities provide greater consistency and quality assurance. A factory that controls the entire production cycle—from raw aluminum billet casting to extrusion, finishing, and panel assembly—ensures tighter tolerances, better load-bearing capacity, and fewer errors in formwork fitting.

Aluminium profiles used in formwork systems need to meet strict technical standards. These include strength ratings, surface flatness, dimensional accuracy, and resistance to deformation under pressure. A professional supplier will test and certify their materials to comply with international codes, making their systems ideal for high-rise buildings, commercial complexes, and infrastructure projects.

Beyond formwork, aluminium profiles serve multiple architectural and industrial uses. They are widely used in framing, support beams, partition systems, and modular construction setups. Suppliers that offer diversified product lines across construction, solar, transport, and decoration industries provide added value to clients seeking a long-term sourcing partner.

What sets reliable aluminium profiles suppliers apart is their ability to balance precision engineering with large-scale production. They must be capable of fulfilling high-volume orders while maintaining customization flexibility. Surface treatments such as anodizing, powder coating, and electrophoresis are often applied to enhance durability and visual appeal.

Working with an experienced aluminium formwork supplier also offers engineering support. From early-stage project consultation to post-sales technical assistance, strong customer service ensures that the formwork integrates seamlessly into the site workflow. This end-to-end approach helps avoid costly delays or assembly issues.

As global construction standards continue to emphasize efficiency and sustainability, aluminium formwork and profile systems are increasingly favored for their long lifecycle, recyclability, and performance. Choosing a supplier with a proven track record, factory strength, and a wide product range is a key step in future-proofing any construction project.