Aluminum profiles have become increasingly popular in furniture design due to their versatility, durability, and aesthetic appeal. With a wide range of shapes, sizes, and finishes available, choosing the right aluminum profile for your furniture project can be daunting. This article will provide a comprehensive comparison of different types of aluminum profiles for furniture, examining their key features, advantages, and applications.

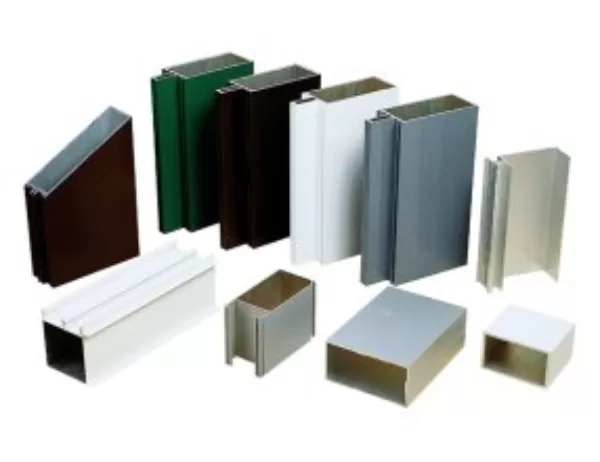

Extruded aluminum profiles are created by forcing molten aluminum through a die to shape it into a specific cross-section. This process allows for precise and complex designs with high strength-to-weight ratios.

Advantages:

High strength and durability

Complex and intricate designs possible

Lightweight and easy to handle

Corrosion-resistant and weather-resistant

Applications:

Structural components of furniture, such as frames and legs

Decorative and aesthetic elements, such as trim and moldings

Outdoor furniture and marine applications

Rolled aluminum profiles are produced by rolling flat aluminum sheets to achieve the desired thickness and width. This method offers a smoother surface finish and tighter dimensional tolerances.

Advantages:

Smooth and aesthetically pleasing surface

High dimensional accuracy

Good formability and malleability

Lightweight and durable

Applications:

Furniture panels and covers

Cabinet doors and drawers

Decorative surfaces and architectural trim

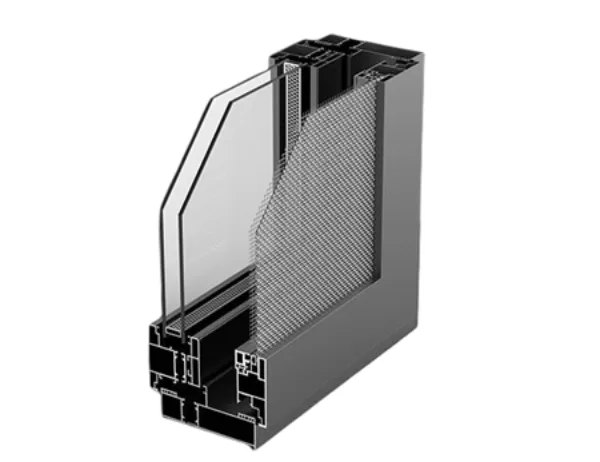

Hollow aluminum profiles are extruded or rolled profiles with a hollow interior. This design provides lightweight and rigid structural components.

Advantages:

High strength-to-weight ratio

Lightweight and easy to transport

Excellent insulation properties

Corrosion-resistant and durable

Applications:

Furniture frames and legs

Exhibition and display systems

Aerospace and automotive industry

Composite aluminum profiles combine aluminum with other materials, such as wood, plastic, or rubber, to create profiles with unique properties. This combination offers the benefits of both materials.

Advantages:

Enhanced strength and durability

Improved thermal and sound insulation

Increased design possibilities

Lightweight and cost-effective

Applications:

Furniture with ergonomic handles and grips

Structural components that require both strength and insulation

Decorative elements with unique textures and finishes

Selecting the right aluminum profile for your furniture project depends on several factors, including:

Load-bearing requirements: Extruded aluminum profiles offer the highest strength for load-bearing applications.

Aesthetic considerations: Rolled aluminum profiles provide a smooth and elegant surface finish.

Weight constraints: Hollow and composite aluminum profiles offer lightweight solutions.

Cost: Rolled aluminum profiles tend to be more cost-effective than extruded profiles.

By carefully considering these factors, you can select the optimal aluminum profile to meet the specific requirements of your furniture design.