As someone who’s sourced components for packaging equipment for over 15 years, I’ve seen aluminum profiles become the backbone of reliable machinery. That 100mm aluminium tube you see in modern packaging systems? It’s not there by accident.

The Unseen Framework

Early in my career, I watched a steel-framed packaging machine warp under constant use. When we switched to aluminum profile manufacturers for the frame, the difference was remarkable. The same machine ran cooler, lasted longer, and weighed 40% less – making floor reconfigurations actually possible.

Precision That Matters

Not all aluminum section manufacturers understand packaging needs. I learned this the hard way when improperly milled profiles caused vibration issues in a high-speed flow wrapper. The right aluminium extrusion suppliers provide tolerances within 0.1mm – crucial for maintaining seal integrity at 200 packages/minute.

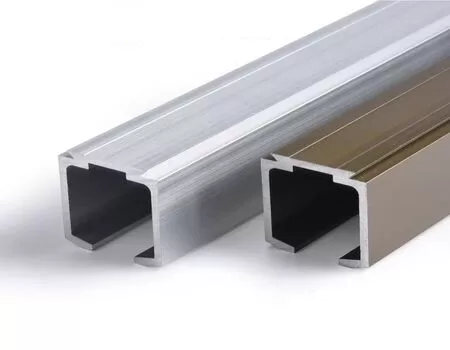

Why 100mm Tubes Dominate

Through trial and error, we’ve found 100mm aluminium tubes offer the perfect balance between rigidity and weight for most packaging machine frames. They accommodate internal wiring neatly while withstanding the torque of automatic feeding systems. Smaller diameters flex; larger ones waste material and space.

The Supplier Difference

Not all aluminum profile suppliers are equal. The best aluminium section manufacturers now offer custom anodizing – a game changer for food-grade packaging equipment where corrosion resistance is non-negotiable. This attention to detail separates adequate machinery from exceptional performers.

Future-Proofing Investments

Modern aluminum profile manufacturers are helping us build packaging machines that last. With the right aluminium extrusion suppliers, we’re creating equipment that maintains precision through three shifts of continuous operation. That reliability translates directly to lower maintenance costs and higher output.

The packaging machines making waves today all share one thing: intelligently sourced aluminum components. When every micron and minute counts, the right extrusion partner becomes your silent competitive advantage.