Introduction

Industrial aluminum profiles and steel are two commonly used materials in various industries. Each material offers unique advantages and disadvantages, making it essential to understand their properties before selecting the best option for specific applications. This comparative analysis will delve into the key aspects of industrial aluminum profiles versus steel, examining their strength, durability, corrosion resistance, weight, cost-effectiveness, and ease of fabrication.

Steel is renowned for its exceptional strength, making it suitable for applications where high load-bearing capacity is required. However, aluminum profiles can also provide comparable strength, especially when reinforced with proper alloys and heat treatments. In terms of durability, both materials exhibit excellent resistance to wear and tear, making them ideal for industrial environments.

Aluminum profiles have a distinct advantage over steel in terms of corrosion resistance. Aluminum forms a protective oxide layer on its surface, which prevents further corrosion in most environments. Steel, on the other hand, is susceptible to rusting in the presence of moisture and oxygen. This makes aluminum profiles a more suitable choice for applications in corrosive environments, such as marine or chemical settings.

Aluminum is significantly lighter than steel, making it an ideal material for applications where weight is a critical factor. The lower weight of aluminum profiles enables efficient handling, transportation, and installation, which can translate into cost savings and environmental benefits.

The cost of aluminum profiles can be higher than that of steel, especially in bulk quantities. However, the long-term cost benefits of aluminum, such as its durability and low maintenance requirements, make it a cost-effective choice in the long run. Steel may offer lower upfront costs, but its susceptibility to corrosion and the need for regular maintenance and protective coatings can offset these initial savings.

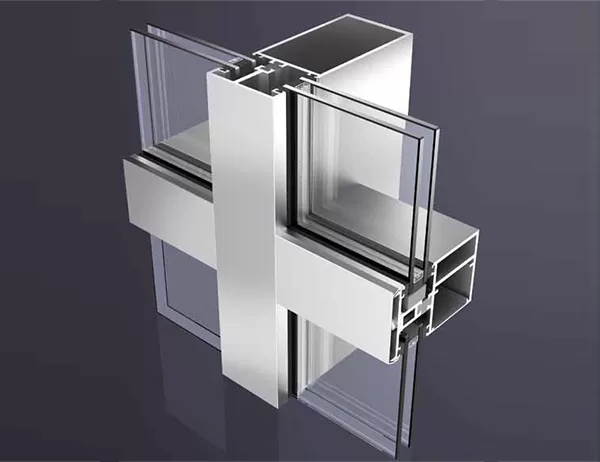

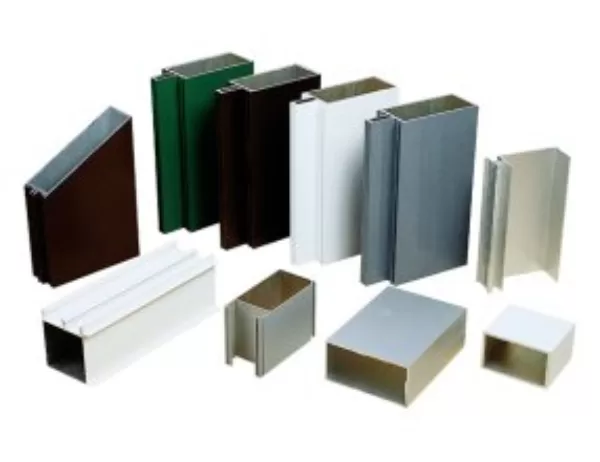

Both aluminum profiles and steel are relatively easy to fabricate and can be formed into various shapes and configurations. Aluminum profiles, however, have an added advantage due to their extrusion process. Extrusion allows for the production of complex profiles with intricate geometries, which may be difficult to achieve with steel.

Industrial aluminum profiles and steel offer distinct advantages and disadvantages. While steel provides exceptional strength and durability, aluminum profiles excel in corrosion resistance, weight, and cost-effectiveness in the long run. The specific requirements of each application will determine the best choice between these two materials. By understanding the strengths and limitations of both aluminum profiles and steel, engineers and designers can make informed decisions that optimize performance, longevity, and cost-effectiveness in industrial applications.