In the realm of renewable energy, where innovation thrives, the manufacturing of aluminum solar panel frames stands as a testament to human ingenuity. These frames serve as the skeletal foundation upon which the solar panels are mounted, ensuring their durability and longevity amidst the relentless forces of nature.

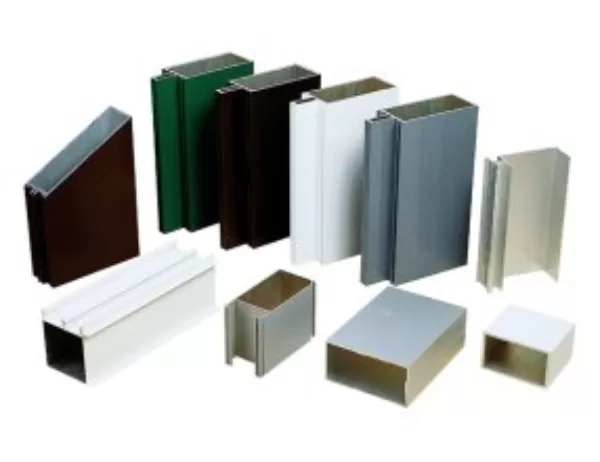

Extrusion: The Crucible of Aluminum Alchemy

The journey begins with the extrusion process, where molten aluminum heated to blistering temperatures is forced through a meticulously designed die. As the viscous metal snakes its way through the die, it solidifies, taking on the desired shape and cross-sectional dimensions. This extruded aluminum profile forms the backbone of the solar panel frame.

Anodizing: Enhancing Durability with an Electrochemical Shield

Next, the extruded aluminum undergoes anodization, an electrochemical process that transforms the metal’s surface into a protective oxide layer. This layer not only enhances the frame’s resistance to corrosion and wear but also improves its electrical insulation, ensuring the safe and efficient flow of current.

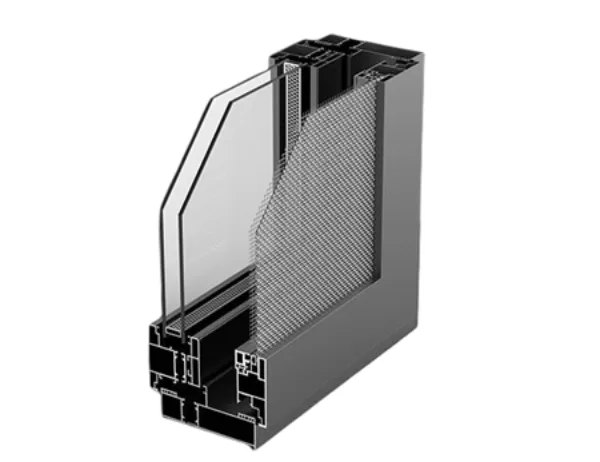

Cutting and Assembly: Crafting a Precise Framework

With the anodization complete, the aluminum profiles are subjected to precision cutting and joining techniques. Laser cutting ensures accurate and clean cuts, while specialized welding processes firmly fuse the profiles together, creating a structurally sound and weather-resistant frame.

Mounting and Profiling: Ensuring Optimal Performance

Once the frame is assembled, it is mounted onto the solar panels. Careful consideration is given to the panel’s dimensions and weight to ensure a perfect fit. Additionally, the frame is profiled to allow for proper ventilation and thermal dissipation, preventing overheating and performance degradation.

Quality Control: Ensuring Excellence

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the highest standards of workmanship. Automated inspection systems detect imperfections, while manual inspections verify the dimensional accuracy, strength, and durability of each frame.

Conclusion

The manufacturing of aluminum solar panel frames is an intricate process that requires meticulous attention to detail and a deep understanding of materials science. From the extrusion process that shapes the aluminum to the anodization that protects and enhances its surface, each step is designed to create a frame that epitomizes durability, functionality, and aesthetic appeal. As the demand for renewable energy continues to rise, the aluminum solar panel frame stands as a testament to human ingenuity, paving the way for a cleaner and more sustainable future.