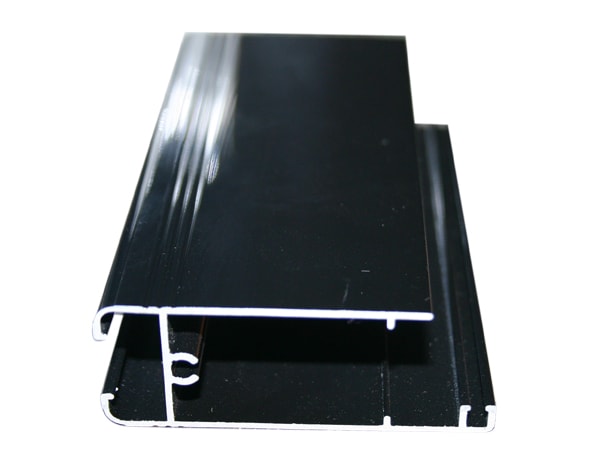

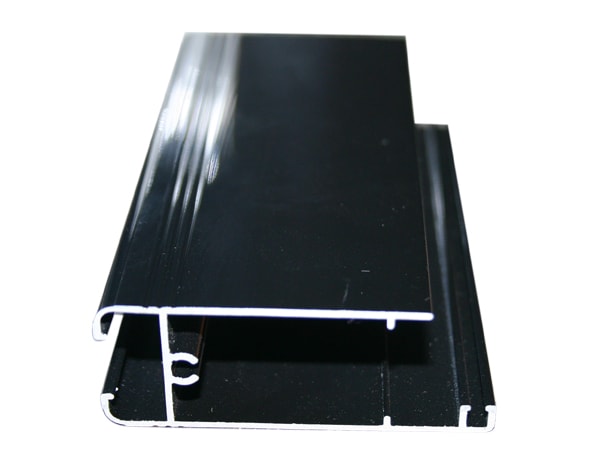

Aluminium extrusion for Black Electrophoresis

Product Details

Technology: Aluminum Extrusion

Normal Anodizing thickness: 8-12 micro

Normal Power Coating thickness: 60-100 micro

Shape: Square, Round, Flat, or customized

Length: The Standard length of export is 5.8m , Anodizing 6.5 meters at most, Mill finish 13 meters at most according to customers' drawings

Deep processing:cutting, drilling, punching, bending etc.

Engineering& Tooling:1: 8 Engineers in Mold Shop. 2: Use high tonnage extruder, Wire EDM, CNC, Drilling machines etc.

Material: Aluminium Alloy 6063, 6063A, 6060, 6061,6005

Temper available: T4, T5, T6, etc.

Feature of Electrophoresis:

High corrosion resistance.

Long lasting, not aging, do not fade, do not fall off.

Excellent material for smooth and subtle edges, elegant appearance.

High hardness of the film.

Principle: Electrophoresis is one of the most effective ways to paint metal parts. Electrophoretic coating is the conductive coating is immersed in the water filled with water dilution of the relatively low concentration of electrophoretic coating tank as the anode (or cathode), in the tank and set the corresponding cathode (or anode), in the poles Indirect direct current after a period of time, the surface of the coating was deposited evenly fine, not water-soluble coating of a special coating method.

Application: can be divided into anodic electrophoretic paint, cathodic electrophoretic paint. One anodic electrophoretic paint anode acrylic, mainly used in aluminum products, aluminum oxide with anodic electrophoretic paint protection, gloss between 50-90 degrees, thin film, widely used in the aluminum industry.

Factory