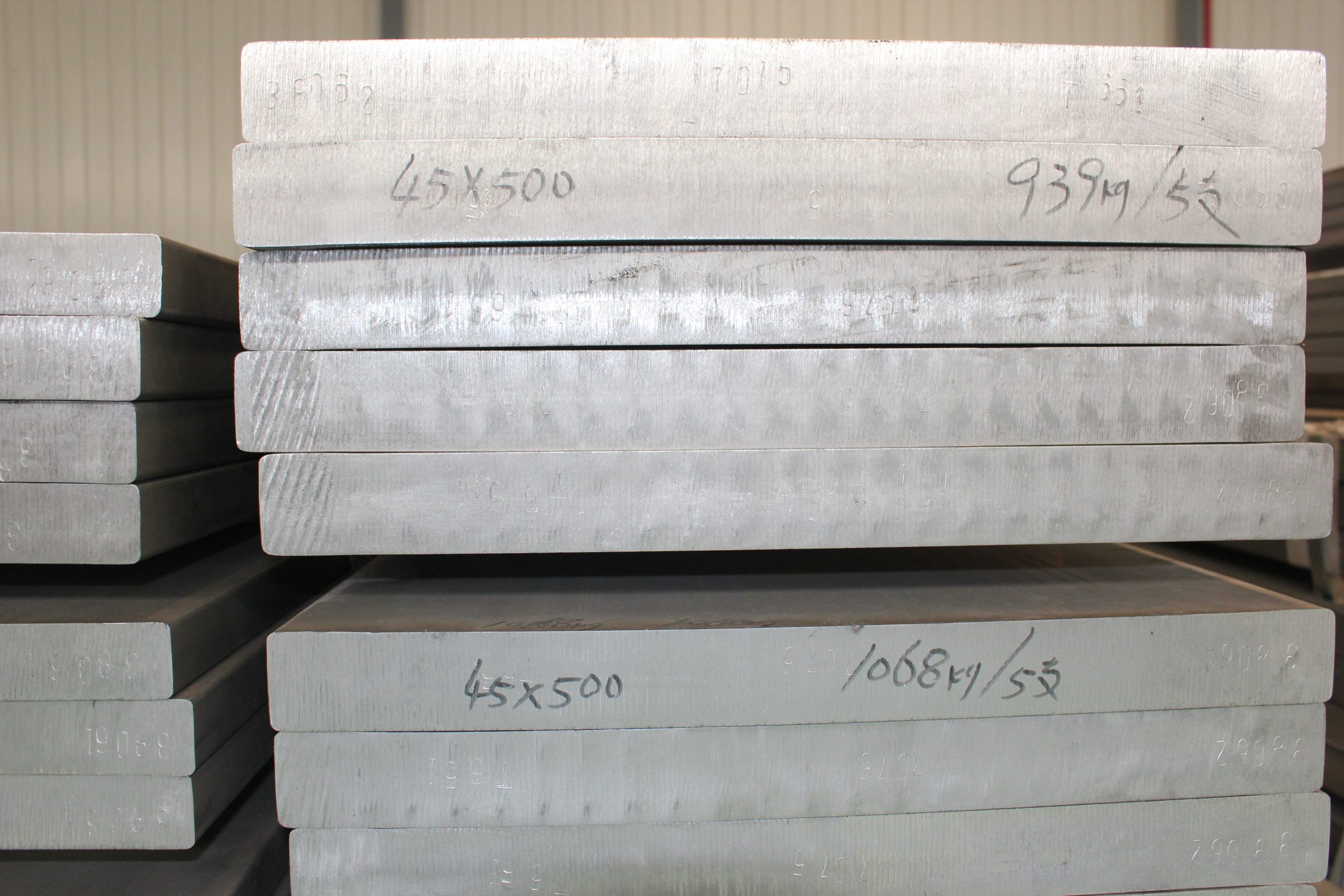

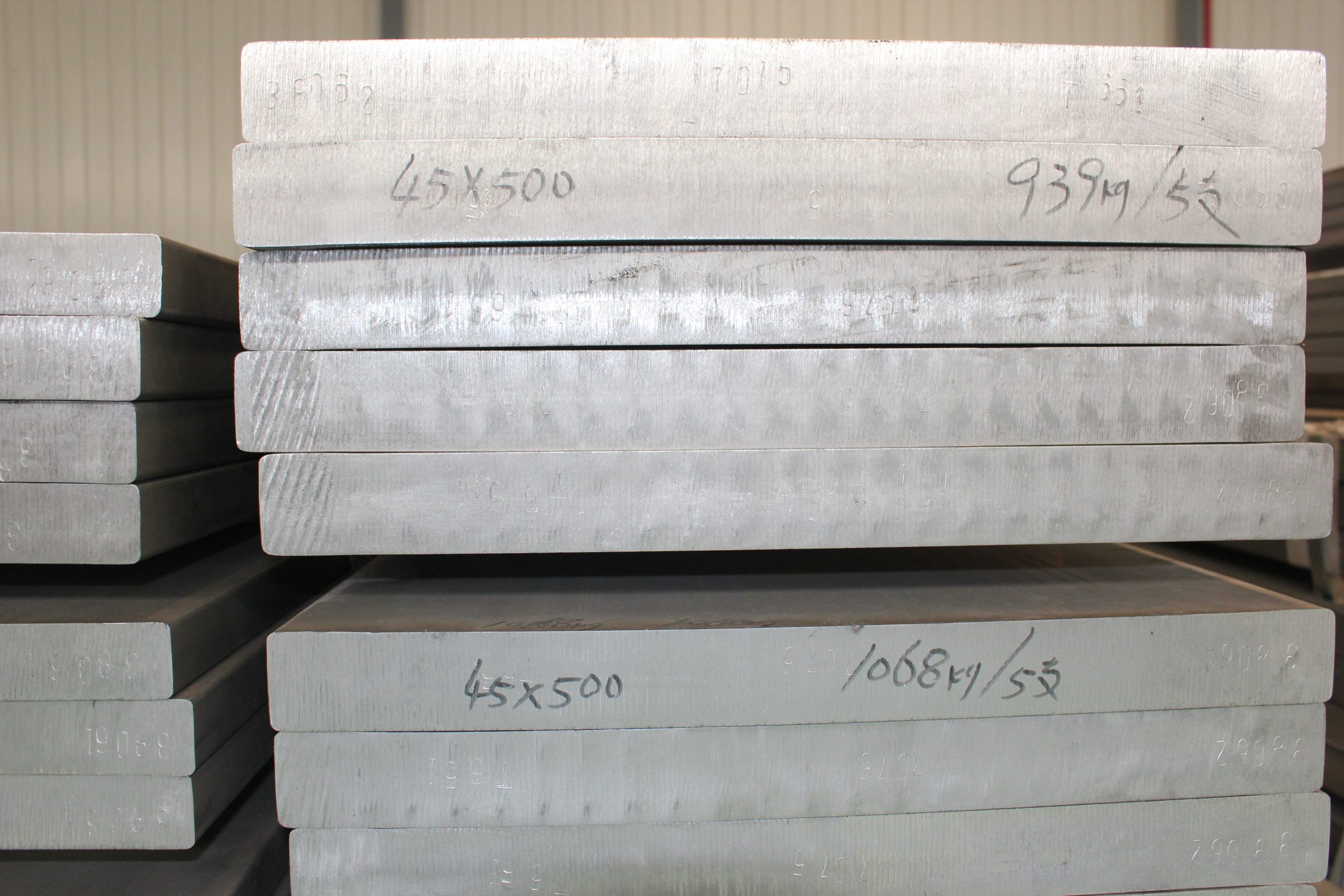

2series aluminium alloy extrusion

Product Details

Product description:

Features: 2 series Aluminum alloy containing copper as the main element, and manganese, magnesium and bismuth are also added for machinability. Such as: 2011 alloy, pay attention to safety protection during smelting (will produce harmful gases). The 2014 alloy is used in the aerospace industry and has high strength. The 2017 alloy has a lower strength than the 2014 alloy, but it is easier to process. 2014 alloy can be strengthened by heat treatable processing.

Application:

aviation industry, screws and industries with higher temperature.

The following are the 2 series aluminum alloys that our company can produce:

Alloy: H112、T351、T4、T6、T651 Length: 7m-14m Product diameter: 100mm-600mm

Product:

Aluminium alloy tube,aluminium alloy bar,aluminium alloy bar

Package:

1. Bare package;

2. waterproof cloth / plastic film wrapping, steel band bundling, wooden pallet bottom;

3. cube packaging, wooden pallet bottom, steel band bundling

Product advantages:

1. Sophisticated production technology, advanced equipment. The main production equipment and testing equipment are imported from abroad

2. High precision, high strength, corrosion resistance and wear resistance

3. The technical center (central laboratory) has been assessed as the Qinghai Engineering Technology Center. It is not only capable of analyzing the chemical composition of the aluminum alloy tube and rod production, metallurgical structure inspection, and mechanical property testing, but also can meet the needs of new product and new process development.

4. Certificates to prove quality:

Shipment:

Standard loading quantity:

1*20GP:Max .length:5.85 meters Loaded quantity: 10 to 12 tons

1*40HQ:Max. length:12 meters Loaded quantity: 22-26 tons

Standard export port:

Huangpu/ Foshan or Shenzhen

Type of shipping:

Shipment by sea; by road; by train; multi-transportation.

Knowledge

Chinese Aluminum Extrusions is used by many different industries. They are the fastest way to complete projects. Aluminum extrusion is a process that uses aluminum alloy to shape a part or object in a certain way. They can be used in the area of sheet metal fabrication, air conditioning and refrigeration applications, in Pharmaceutical industries, in Medical Equipment and more. The Chinese aluminum extrusions are very strong and durable.

They have many advantages over cast iron or steel. It is extremely easy to work with and will not bend, warp or even crack in any sort of way. Chinese aluminum extrusion products can also be shaped, for example, in the shape of an aircraft wing. This is very popular in the aerospace industry and is used to manufacture parts that have to withstand the G forces they will endure during flight. They are also often used to create the edge features on wings and tails.

The aluminum extrusions that are made in China are lightweight and strong. They have a much thinner material than other types of aluminum and can be thin enough to be used in thin sheets. They are very cost effective, which makes them a good choice for companies looking to cut cost and/or reduce manufacturing overhead. They can be manufactured at a much faster rate than other aluminum alloys and are much cheaper than steel. Aluminum weighs about half a pound per square inch, which makes it a very attractive choice in places where space is limited.

Chinese aluminum extrusions come in several different varieties. There are several forms of the basic product, including tubes and sheets. The tubes are commonly used for components that need to be mounted close together and then joined. They are frequently used in medical applications to create artificial hips and joints. The sheets are most commonly used to make window frames and air conditioner vents. Each of these varieties has its own set of benefits and drawbacks, so it's important to consider which option would best meet your needs before making a purchase.

It's important to note that aluminum is a soft metal. This means that they are more prone to scratching and denting than other metals. However, this also means that they are stronger and less likely to break than steel. If you have items in your home or office that are especially valuable, you may want to think about investing in Chinese aluminum extrusions. They have the strength and durability to support your investment and add beauty to your home or workplace.

Another thing to keep in mind is that Chinese aluminum extrusions are not actually aluminum itself. They are actually zinc and copper alloys. In many cases, you will see a picture of a bird with its wings outstretched. This is because the copper wire has been woven tight between two of the metal plates inside the bird's body. When the wire is folded back, it forms the bird's wings, which gives you an idea of how this material is used.

Factory