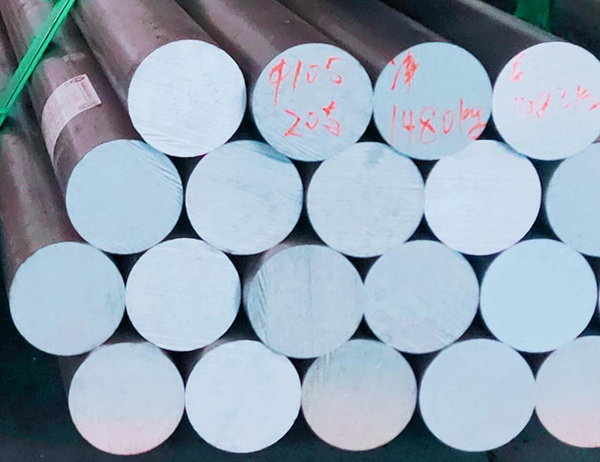

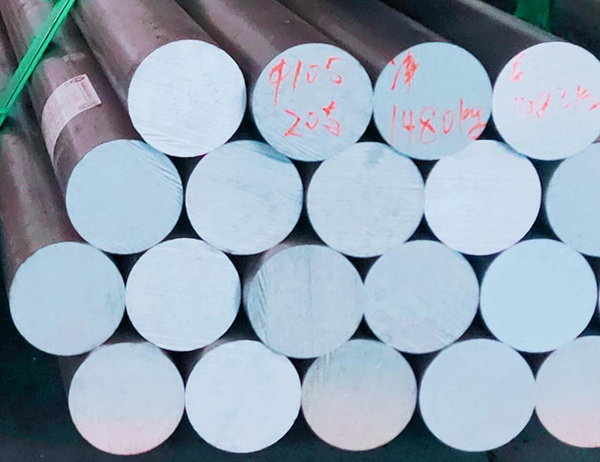

7Series Aluminium Alloy Extrusion

Product Details

Product description:

Features:

7 series aluminum alloys are mainly zinc, but sometimes a small amount of magnesium and copper are added. Among them, super-hard aluminum alloys contain zinc, lead, magnesium and copper alloys close to the hardness of steel. The extrusion speed is slower than 6 series alloys, and the welding performance is good.

Applications:

Aviation (bearing components of aircraft, landing gear), rockets, propellers, aviation spacecraft.

The following are the 7 series aluminum alloys that our company can produce:

Alloy:7005、7075、7A04 Temper:T5、T6、T651 Length:7m-14m Product Diameter:100mm-600mm

Product:

(1) Bare Package;

(2) Waterproof Cloth / Plastic Film Wrapping, Steel Band Bundling, Wooden Pallet Bottom;

(3) Cube Packaging, Wooden Pallet Bottom, Steel Band Bundling

Product Advantages:

(1) Sophisticated production technology, advanced equipment. The main production equipment and testing equipment are imported from abroad

(2) High precision, high strength, corrosion resistance and wear resistance

(3) The technical center (central laboratory) has been assessed as the Qinghai Engineering Technology Center. It is not only capable of analyzing the chemical composition of the aluminum alloy tube and rod production, metallurgical structure inspection, and mechanical property testing, but also can meet the needs of new product and new process development.

(4) Certificates to prove quality:

01 Weaponry equipment research and production license

02 National Industrial Production License

03 Quality management system certification

04 Environmental management system certification

05 Occupational health and safety management system certification

Shipment:

Standard loading quantity:

1*20GP:Max .length:5.85 meters Loaded quantity: 10 to 12 tons

1*40HQ:Max. length:12 meters Loaded quantity: 22-26 tons

Standard export port:

Huangpu/ Foshan or Shenzhen

Type of shipping:

Shipment by sea; by road; by train; multi-transportation.

Knowledge

If you are wondering what aluminium section extrusions are then I will provide a clear description. Sectional extrusions (or simply extrusions) are used in the manufacturing of precision aluminium alloys. This is because such materials require precision cutting as they are very thin. In addition to that, the alloy used for these sections need to be as smooth as possible to prevent any problems associated with casting, painting and forging. All this means that the material used must have a very fine tolerance to weight and heat and this is where section extrusions come in.

When looking at aluminium section extrusions you will see that each strip is precision cut to specific dimensions. They can then be welded or glued together to form a part. One of the most popular applications for them is in the aerospace and defense industry where precision engineering is a priority. In order to create the most aerodynamic parts that are possible the materials used must be as smooth as possible to reduce the drag they experience whilst in flight. A smooth piece of metal with sharp edges on it is not aerodynamic and will not perform well.

As an example, take an aluminium tube which has been rolled out to form a wing. If the edges of the tube are sharper than the rest of the piece then it will cause the air around it to have a rough texture. However, with aluminium t section extrusions the edges of the strips are perfectly machined to be as smooth as possible and this means that they act as the best aerodynamic part of the wing as it is traveling through the atmosphere at more than Mach speeds.

Another application of section extrusions is in the aerospace and defense industry. Some of the most advanced weapons in the world are made from aluminium. The materials used in them are highly specialized but also very robust and extremely light in weight making it perfect for the high stresses and speeds that these objects must withstand. The same properties can be found in aluminium t section extrusions and they are often found in the bodies of missiles such as missiles which have large fins or some type of missile launch system. The same properties can also be found in bullet-proof vests and other armor types and so using aluminium t-section extrusions inside these objects will allow them to be just as tough and effective as bullet-proof vests whilst keeping the weight down so they can be lighter and cheaper to use.

Sectionals are usually found in areas where there is a large amount of cold air and low humidity. These can include in the engines of planes and helicopters, ships and trucks, as well as many industrial applications. As the air travels along the aluminium strips it is pushed along into the correct place by the air pressure. As the aluminium travels along the material becomes smoother and thus the part becomes more rigid and less likely to buckle or get damaged as a result of the bumps and vibrations caused by the passing air. As an example of this is seen in how bullet-proof vests stop bullets from penetrating the vest, but when it comes to aluminium t section extrusions these materials are able to absorb and cushion the impact meaning that the vest does not buckle or tear at all thanks to the fact that the material is so smooth.

As these are made out of aluminium t section extrusions can be used for a variety of different things which include bullet-proof vests, bullet-resistant vests, and even protection from fire. This is due to the fact that they are the perfect materials for this sort of protection. Aluminium has the ability to bend, but it has the ability to be shaped so that if an impact is placed on it the ability to bend it and absorb the impact without any damage is preserved. This means that if you were to hit your arm with something hard enough to crack your fibers in two and then another hard enough to cause a similar sort of crack in the next fiber would not prevent you from getting hurt. This therefore means that if you were looking to use one of these material t sections for protection on your arms you will not have to worry about anything happening to your skin in the event of an impact.

Factory